- Introduction - 6HX511 Structural Design Project Assignment Sample

- Design Calculations

- Structural Elements Design

- Connection Details

- Bracing and Shear Walls

- General Arrangement Drawings

- Method Statement and Construction Program

- Stability check for the design is done using the Finite Element (FE) Analysis

- FE Analysis Software

- Results and Comparison

- Adjustments and Optimization

Introduction - 6HX511 Structural Design Project Assignment Sample

This paper offers the specific outline and evaluation of the proposed medical center construction, with the emphasis upon the suggested solution of the steel frame with composite floors. The goal of the project is to provide and accomplish a facility construct that will be sustainable, cost optimally efficient, structurally safe and effectively functional for the clients as well as compliant with the updated Eurocode requirements. The report also contains detailed design checks for all main structural components, GA drawings of structures suitable for fabrication and general construction, method statement for safe construction and FE analysis for structural stability. The specific design of the steel frame provides the following benefits: shorter construction period, lower calculated embodied carbon, and easier modifications in the future. It provides the readers with a general background concerning the whole project, an introduction adequate to the technical and analytical data discussed further.

Need a reliable Assignment Helper to boost your grades? We provide comprehensive academic support tailored to your needs, helping you achieve the results you deserve without the stress.

Design Calculations

Recommended size for the proposed medical center buildings; An analysis and design of the structural calculations for the steel frame with composite floors is essential for constructing the building. This section describes how the main structural frameworks are determined such as beams, columns, floor slabs and roofs and foundations. Also, it includes connection information and the layout of the bracing systems necessary for the job of steel structure.

Structural Elements Design

Beams:

The concept of beam deals with selection and confirmation of suitable size and grade of steel for withstanding of load to be imparted. Primary beams on which floor slabs and secondary beams rest are meant for taking up heavy loads and bridging greater spans. Here, secondary beams also bear the weight of floor slabs above but are suited for smaller spans on the network (Watson et al. 2023). The design of the beam takes into account factors like the bending moments, the shear forces among other factors the deflection limits. The primary beams are made from UB650 x 325 x 185 kg/m while the secondary beams from UB475 x 200 x 89 kg/m to allow enough strength and stability.

Data

Span (L) = 9.5 m

Imposed load-

Floor & roof garden = 5 kN/m2

SDL = 1.5 kN/m2

Steel grade = S355J2+N

Yield strength (fy) = 355 MPa

Ultimate tensile strength (fu) = 470 MPa

Concrete grade = C30/37

Concrete compressive strength (fck) = 30 MPa

Calculation

Loading (unit area) Qtotal = QSDL + Qlive = 1.5 + 5.0 = 6.5 kN/m2

Width of beam tributary (bt) = 3.5 m

Design beam load (Qb) = Qb x bt = 6.5 x 3.5 = 22.75 kN/m

Loading (unit area) Qtotal = QSDL + Qlive = 1.5 + 5.0 = 6.5 kN/m2

Width of beam tributary (bt) = 3.5 m

Design beam load (Qb) = Qb x bt = 6.5 x 3.5 = 22.75 kN/m

Factored Load (Qb,ed) = 1.35 QSDL + 1.5 Qlive

Qb,ed = 1.35 x 1.5 + 1.5 x 5 = 27.125 kN/m

Maximum Moment (Med) = Qb,ed L2/8 = 27.125 x 9.52/8 = 306.1 kNm

Maximum Shear Force (Ved) = 27.125 x 9.5/2 = 128.4 kNm

Let consider section UB 650 x 325 x 185

A = 20100 mm2

Iy = 196.9 x 106 mm4

Plastic Modulus (Wpl) = 823 x 103 mm3

Plastic Moment capacity (Mrd) = Wpl x fy/ ⋎mo = (823 x 103 x 355)/(1 x 106)

Mrd = 291.17 kNm

Shear resistance (Vrd) = A x fy/√⋎mo = (20100 x 355)/(√3 x 1 x 106)

Vrd = 1031.0 kN

Vrd > Ved (hence ok)

Allowable deflection (δallowable) = L/250 = 9500/250 = 38 mm

Actual Deflection (δactual) = 5 Qb,ed x L4/384 x E x Iy

δactual = 5 x 27.125 x 9.54/384 x 210 x 196.9 x 106

δactual = 18.0 mm

δactual < δactual (hence ok)

Composite beam design

Beam = UB 650 x 325 x 185

Slab thickness = 150 mm

Effective width (beff) = L/4 = 9.5/4 = 2.375 m = 2375 mm

Using shear stud of 100 mm height and 19 mm dia.

Concrete grade C30/37

Design compressive strength fcd = fck/γc = 30/1.5 = 20 MPa

Elastic modulus of concrete (Ec) = 22 x (fck/10)0.3

Ec = 31.1 GPa

Effective area of slab (Ac) = beff x tslab

Ac = 2375 x 150 = 356250 mm2

Modular ratio (n) = Es/Ec = 210/31.1 = 6.76

Net concrete area (Ac,eff) = Ac/n = 356250/6.76 = 52710 mm2

Depth of neutral axis from bottom (hNA) = (As x ys + Ac,eff x yc)/(As + Ac,eff)

Here,

ys = 191 mm

yc = 517 mm

hNA = (9450 x 95.5 + 42155 x 517)/(9450 + 42155)

hNA = 442.5 mm

Lever arm (z) = h - hNA = 517 – 442.5 = 74.5 mm

Plastic moment of resistance (Mrd,comp) = Fc x z

Here,

Fc = 0.85 x fcd x Ac = 0.85 x 20 x 356250 = 6037500 N

Mrd,comp = 6037500 x 0.0745 = 449.8 kNm

Mrd,comp > Med (hence safe)

Flow of shear (Vs) = Fc/L = (6037500)/9.5 = 635 kN/m

Connector resistance (Pr) = 0.8 Φ2 x fu = 0.8 x π x (19/2)2 x 450 = 64.1 kN

Connector number per meter length (N) = Vs/ Pr = 635/64.1 = 10

Providing 10 connectors per meter @ 125 mm c/c.

Minimum reinforcement (ρmin) = 0.0013

beff = 2375 mm

As = ρmin x beff x tslab = 0.0013 x 2375 x 150 = 463.1 mm2

Providing 12 dia bars @ 200 mm c/c.

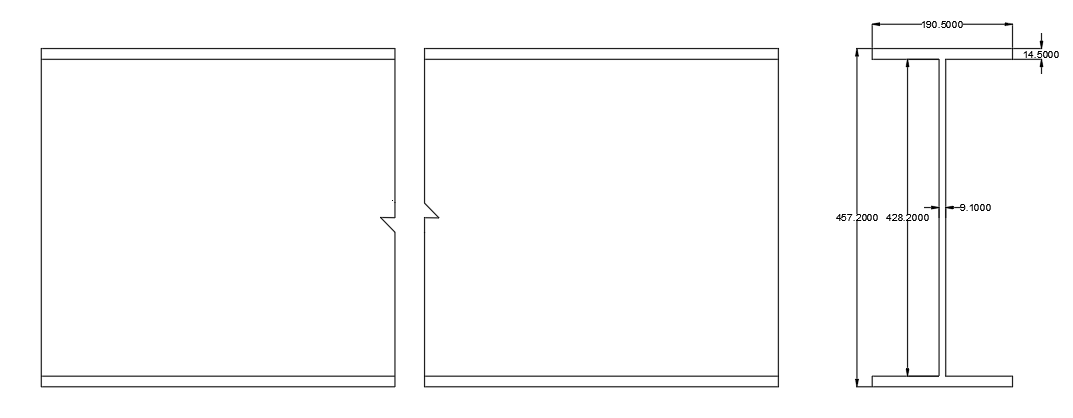

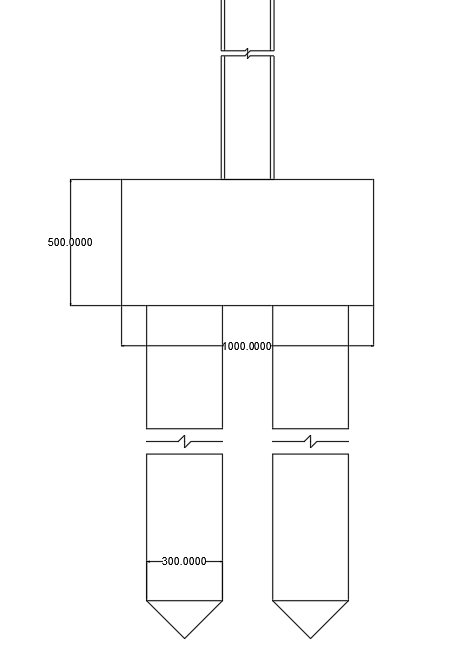

Figure 1: Beam Details

(Source: Self-created in Auto CAD)

Columns:

Beams, floor slabs and roofs transfer their own loads and additional loads directly on to the columns. The width of the column may also differ due to the amount of load it has to support as well as its place in the construct. To the basement and ground floor levels though more loads are transferred, UC 600 x 750 x 315 kg/m column sections are recommended (Cao et al. 2022). The typical UC 450 x 600 x 210 kg/m sections are used in the ground floor to roof level columns. Axial loads, moments, and the buckling resistance of the columns are taken into account in the design of the structure.

Data

Floor to floor height = 4.7 m

Steel grade = S355

Steel yield strength (fy) = 355 MPa

Steel design strength (fyd) = fy/γmo = 355/1 = 355 MPa

Calculation

D.L (G) = 5 x 9.5 x 4.7 = 166.25 kN

L.L (Q) = 6.5 x 9.5 x 4..7 = 216.225 kN

Factored Load (Ned) = 1.35 G + 1.5 Q

Ned = 1.35 x 166.25 + 1.5 x 216.225

Ned = 482.94 kN

Considering a UC 400 x 450 x 315 column

A = 31500 mm2

Iy = 228.8 x 106 mm4

Radius of gyration (ry) = 120.7 mm

Plastic modulus (Wpl) = 1370 x 103 mm3

Axial resistance (Nrd) = A x fyd = 31500 x 355/103

Nrd = 11192.5 kN

Nrd > Ned (hence safe)

Slenderness ratio (λ) = Leff/ry

λ = 3500/120.7 = 29.04

Non-dimensional slenderness (λnd) = √(A x fyd)/(π2 x E x Iy)

λnd = √(31500 x 355)/( π2 x 210000 x 228.8 x 106)

λnd = 0.588

χ = 1/Φ + √Φ2 – λ2

Φ = 0.5 x [1 + α (λnd – 0.2) + λ2nd]

Here, α = 0.49

Φ = 0.5 x [1 + 0.49 x (0.588 – 0.2) + 0.5882]

Φ = 0.912

χ = 1/0.912 + √0.9122 – 0.5882

χ = 0.798

Buckling resistance (Nb,rd) = χ x A x fyd

Nb,rd = 0.798 x 31500 x 355/106

Nb,rd = 8850.6 kN

Nb,rd > Ned (hence safe)

Considering the eccentricity value = 50 mm

Factored moment (Med) = Ned x e = 482.94 x 0.05 = 24.15 kNm

Moment of resistance (Mrd) = Wpl x fyd = 1370 x 355/106 kNm

Mrd = 486.35 kNm

Med < Mrd (hence ok)

Combined bending & axial interaction-

Ned/Nb,rd + Med/Mrd ≤ 1

482.94/8850.6 + 24.15/486.35 = 0.0545 + 0.0497 = 0.1042 <1 (hence safe)

Figure 2: Column Details

(Source: Self-created in Auto CAD)

Floor Slab:

A composite floor slab is used, formed by a steel deck and by a topping of reinforced concrete. The steel deck becomes part of the form for the concrete and act compositely with the concrete to carry loads. The entire thickness of the composite floor is 150 mm of Concrete and 60mm of the deck. The loading also takes into account deflection and stiffness of the composite section, so that the resultant structure could take the loads ensuant on the construction as well as affording a level of comfort to the population of the building. High performance deck profiles like Holorib HR51/150 ensures better performance and durability of the floor system.

Data:

Span (L) = 9.5 m

Imposed load (Floor & roof garden) = 5 kN/m²

Superimposed dead load (SDL) = 1.5 kN/m²

Steel grade = S355

Concrete grade = C30/37

Concrete compressive strength (f_ck) = 30 MPa

Slab thickness = 150 mm

Effective width (b_eff) = L / 4 = 9.5 / 4 = 2.375 m = 2375 mm

Calculation:

- Loading (unit area) (Q_total):

- Width of beam tributary (b_t):

- Design beam load (Q_b):

- Factored Load (Q_b,ed):

- Maximum Moment (M_ed):

- Maximum Shear Force (V_ed):

- Consider section UB 457 x 191 x 74:

Area (A) = 9450 mm²

Moment of inertia (I_y) = 276 x 10^6 mm^4

Plastic modulus (W_pl) = 595 x 10^3 mm^3

- Plastic Moment Capacity (M_rd):

- Shear Resistance (V_rd):

- Allowable Deflection (δ_allowable):

- Actual Deflection (δ_actual):

- Composite Beam Design:

Beam = UB 457 x 191 x 74

Slab thickness = 150 mm

Effective width (b_eff) = 2375 mm

Using shear stud of 100 mm height and 19 mm dia.

Concrete grade C30/37

Design compressive strength (f_cd) = f_ck / γ_c = 30 / 1.5 = 20 MPa

Elastic modulus of concrete (E_c) = 22 x (f_ck / 10)^0.3 = 31.1 GPa

Effective area of slab (A_c) = b_eff x t_slab = 2375 x 150 = 356250 mm²

Modular ratio (n) = E_s / E_c = 210 / 31.1 = 6.76

Net concrete area (A_c,eff) = A_c / n = 356250 / 6.76 = 52698 mm²

Depth of neutral axis from bottom (h_NA) = (A_s x y_s + A_c,eff x y_c) / (A_s + A_c,eff)

y_s = 191 / 2 = 95.5 mm

y_c = 457 + 60 = 517 mm

h_NA = (9450 x 95.5 + 52698 x 517) / (9450 + 52698) = 433.2 mm

Lever arm (z) = h - h_NA = 517 - 433.2 = 83.8 mm

Plastic moment of resistance (M_rd,comp) = F_c x z

F_c = 0.85 x f_cd x A_c = 0.85 x 20 x 356250 = 6.086 MN

M_rd,comp = 6.086 x 0.0838 = 510.1 kNm

M_rd,comp > M_ed (hence safe)

- Flow of Shear (V_s):

- Connector Resistance (P_r):

- Connector Number per Meter Length (N):

- Minimum Reinforcement (ρ_min):

- Minimum Reinforcement in the Transverse Direction (A_s,min):

Roof:

The roof construction is flat with access for service purposes only included in its construction. The roof needs to be strong enough to support its own weight and the weights placed upon it, as well as any extra loads which may be put on it during maintenance work (Ingraham et al. 2023). The roof structure is designed as a composite system like the floor slab and has a total depth of 150mm of concrete plus 60mm of the deck. geomety and structural depth: under the design loads, this composite section has an adequate resistance and deformability.

Data:

Span (L) = 9.5 m

Imposed load (Roof) = 1.0 kN/m²

Superimposed dead load (SDL) = 1.5 kN/m²

Steel grade = S355

Concrete grade = C30/37

Concrete compressive strength (f_ck) = 30 MPa

Roof thickness = 150 mm (Concrete) + 60 mm (Deck)

Calculation:

Loading (unit area) (Q_total):

Width of beam tributary (b_t):

Design beam load (Q_b):

Factored Load (Q_b,ed):

Maximum Moment (M_ed):

Maximum Shear Force (V_ed):

Consider section UB 457 x 191 x 74:

Area (A) = 9450 mm²

Moment of inertia (I_y) = 276 x 10^6 mm^4

Plastic modulus (W_pl) = 595 x 10^3 mm^3

Plastic Moment Capacity (M_rd):

Shear Resistance (V_rd):

Allowable Deflection (δ_allowable):

Actual Deflection (δ_actual):

Foundations

Data:

Soil bearing capacity = 200 kPa

Column load (N_ed) = 678.94 kN

Column size = 600 mm x 600 mm

Calculation:

Foundation Area (A_f):

Foundation Depth (D_f):

Concrete Volume (V_c):

Concrete Required (m³):

Connection Details

Beam-to-Beam Connections:

The joints by which the beams are arranged also create ways by which these loads are transferred in a safe and effective manner. They mimic the type of connection; for instance, bolted or welded; and size and grade of the connectors. It may therefore be designed to carry the applied moments, shear forces, and axial loads (Jiao et al. 2021). Each connection has end plates and cleats whose detailed dimensions are standardized to have the correct sizes, hence having strong connections.

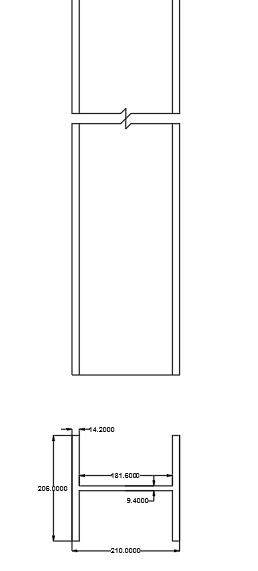

Beam-to-Column Connections:

Figure 3: Beam to Column Details

(Source: Self-created in Auto CAD)

The interaction between beams and columns are stipulated with the work of transferring loads that are exerted on the beams to the column. This depends on the type of connection for example bolted or welded connection and the size and grade of the connection elements. The connections have to perform against the design moments, shear force, and the axial force. It is also worth to mention that standardized connection details including fin plates as well as extended end plates provide stable connections between those elements.

Bracing and Shear Walls

Bracing Systems:

Bracing systems are meant to offerención to the steel frame structure. The design takes into account the kind of bracing, whether it is cross bracing or k-bracing and the size the grade of the bracing members (Millen et al. 2021). The bracing members are intended to withstand the horizontal loads which include wind loads and earthquake loads. The design of the bracing systems follows standard bracing details, which enhance the bracing systems’ strength and reliability.

RC Shear Walls:

Regarding the lateral force resisting system of the steel frame structure, the RC shear walls are incorporated to enhance the lateral force resistance capability. The design takes into account the size and grade of the shear walls and the reinforcement details (Yeh et al. 2023). They are designed to stand the lateral load forces such as the wind and seismic loads in a structure. Standard shear wall details enhance the shear walls strength and stability.

General Arrangement Drawings

These include the general arrangement drawings, which show the plan view, arrangement, position, size and shape of structural plan in proposed medical center building (Gebauer et al. 2022). These drawings consist of the plan, section and elevation which all collectively give detailed layouts of the structural frame of the building.

Plans

It shows the structural plan of the building horizontally for the basement, ground floor, and several additional floors. Key elements depicted in the plans include:

Column Grid: The formation of the columns where the distance between every of them be at least 7 meters apart to guarantee the building stability alongside space utilization. The plans indicate positions of the columns to a finer level of detail extending to the lift/elevator/stair cores.

Beam Layout: Primary and secondary beams refer to these structures which carry the slabs and transfer loads to the columns. On the plans, the length and the direction of the beams cross-sections are also shown.

Floor Slab Layout: The span and elevation details of the composite floor slabs and their detailing indicating the composite action of the steel deck and the reinforced concrete topping (Cabeza et al. 2021).

Core Walls: The positions and positions only of the generally two reinforced concrete core walls that serve as the building’s lateral load bearing walls and are also to enclose the lift/elevator shafts and staircases.

Sections

The section drawings are the vertical sections of the building that demonstrate how one level to another and structural members are positioned. Key elements depicted in the sections include:

Floor-to-Floor Heights: The spans across the width of the building with a minimum clear height of 3 meters and containing mechanical service space of about 0.5 meters.

Column and Beam Heights: The arrangement of columns and beams in the vertical plane with reference to floor slabs and other members.

Roof Structure: The design of the roof structure itself, finishing material of the composite deck and if there are any additional structural elements necessary for maintenance access.

Foundation Details: The scientific works and experiences have shown that strip and pad foundations are most appropriate given the layouts of the foundation and its sufficiency in bearing the loads of the building (Pan & Zhang, 2023).

Method Statement and Construction Program

This document is a Method Statement for Safe Construction of the project.

The construction of the medical center building must be safe without compromise (Douaud et al. 2022). The following Method statement contains safety and construction procedures for the installation of temporary works, construction sequence to ensure construction safety.

Safety Protocols:

Personal Protective Equipment (PPE): The following are considered as minimum safe working practices; Users must wear suitable PPE at all time such a Hard Hat, Safety Glasses, High visibility vest, Safety boots and Gloves.

Site Induction: Provide general inductions for all employees so as to inform them about the various risks peculiar to that site, emergency measures and safety precautions.

Fall Protection: Ensure the use of protection measures including enclosing, not less than four feet vertical height, safety nets, scaffolding toes and harnesses where working at more than twenty-five feet.

Heavy Machinery Operation: Minimize the operation of heavy and dangerous machinery by untrained and unlicensed persons. There is need to inspect and maintain equipments often and well.

Emergency Procedures: Set productive emergency protocols especially the first aid, and fire plus evacuation measures. Make certain that, there is emergency contact information, and there are first aid kits available.

Construction Sequence:

Site Preparation: Eliminate all the accumulated garbage, and other forms of vegetation. Design initial extent and entrances of the site. Post construction barriers and signage.

Foundations: Dig up to the relevant formation level and open up the foundation trenches. Place reinforcement and lay concrete strip and pad foundation. It is thus important that initial and subsequent reactions are allowed to set before continuing the process.

Steel Frame Erection: Install steel columns and beams as per to the drawing and connection detail approved earlier. Screwing will be applied to give a certain degree of rigidity on the frame to allow temporary bracing until completion of frame construction (Bugnot et al. 2021).

Floor Slabs: Lay the steel decking and place the reinforced concrete topping that will complete the composite floor slabs. They should also provide the right curing and finishing of the surface.

Roof Structure: These drawings shall show schematic installations of the roof structure, the composite deck, and other structural components needed for the maintenance of this roof.

Bracing and Shear Walls: The bracing systems and the reinforced concrete shear walls are placed to afford the lateral strength to the structure (Agirre et al. 2023).

Finishing Works: Finish internal and external works comprising walls and floor finishes, glazing, and cladding.

Construction program shall be written down in a manner that requires not more than an A4 size paper, this specific construction programs are the following;

Construction Program

A construction program for the medical center building construction project is intended to help complete construction promptly and on schedule. The program spans 24 months and includes key milestones and phases:

Cost Estimate

| Item | Quantity | Unit | Rate (GBP) | Cost (GBP) | Notes |

| 1. Foundations | |||||

| Bored Piles (600 mm dia) | 100 piles | per pile | 2,500 | 250,000 | Includes drilling, reinforcement, and concreting. |

| Pile Cap (1.8 m × 2.0 m × 0.6 m) | 50 caps | each | 1,800 | 90,000 | Includes concrete, formwork, and reinforcement. |

| Excavation for Piles | 500 m³ | m³ | 25 | 12,500 | |

| Backfilling and Compaction | 200 m³ | m³ | 20 | 4,000 | |

| Sub-Total (Foundations) | 356,500 | ||||

| 2. Superstructure (RC Frame) | |||||

| Columns (UC 400 x 450 x 315 column) | 100 m³ | m³ | 1042 | 104200 | |

| Beams | 150 m³ | m³ | 452.5 | 67875 | |

| RC Slabs (150 mm thick) | 2,236 m² | m² | 60 | 134160 | Includes formwork, concrete, and top/bottom steel. |

| Shear Walls (250 mm thick) | 200 m² | m² | 90 | 18,000 | Includes vertical and horizontal reinforcement. |

| Sub-Total (Superstructure) | 268,200 | ||||

| 3. Steel Frame and Bracings | |||||

| Steel Bracing (CHS 88.9 × 5.0) | 5 tonnes | tonne | 2,400 | 12,000 | Includes fabrication and installation. |

| Beam-Column Connections | 50 pcs | each | 500 | 25,000 | Bolts, plates, and welding costs. |

| Shear Connectors (19 mm dia) | 1,000 pcs | each | 10 | 10,000 | |

| Intumescent Coating | 500 m² | m² | 25 | 12,500 | For 2-hour fire resistance. |

| Sub-Total (Steel Frame) | 59,500 | ||||

| 4. Finishes | |||||

| Internal Walls | 1,200 m² | m² | 25 | 30,000 | Plastering and painting. |

| External Cladding (50% glazed) | 1,100 m² | m² | 200 | 220,000 | Includes glazing and insulated panels. |

| Roof Finishing (Maintenance Use) | 950 m² | m² | 35 | 33,250 | Includes waterproofing. |

| Sub-Total (Finishes) | 283,250 | ||||

| 5. Mechanical and Electrical | |||||

| HVAC Systems | 2,236 m² | m² | 120 | 268,320 | |

| Electrical Installation | 2,236 m² | m² | 80 | 178,880 | Includes wiring, lighting, and outlets. |

| Plumbing and Drainage | 2,236 m² | m² | 50 | 111,800 | |

| Sub-Total (M&E) | 559,000 | ||||

| 6. Other Costs | |||||

| Temporary Works (Scaffolding) | 1,000 m² | m² | 15 | 15,000 | |

| Site Preparation | 1,000 m² | m² | 10 | 10,000 | |

| Safety Measures | Lump sum | 5,000 | 5,000 | ||

| Contingency (10%) | 156,645 | ||||

| Sub-Total (Other Costs) | 186,645 | ||||

| Total Project Cost | 1,730,095 |

Months 1-2: Site Preparation

Site clearance and setup

temporary plants construction

Months 3-6: Foundations

Excavation and foundation work is one of the most typical work types that construction companies have to undertake.

Concrete pouring and curing

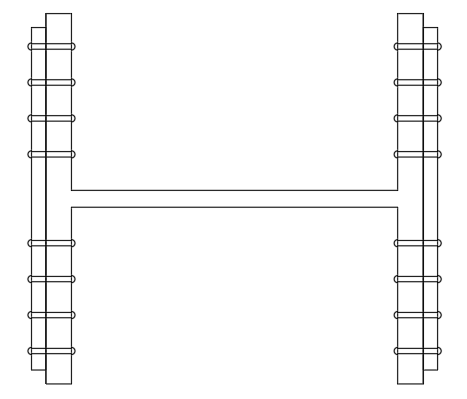

Figure 4: Foundation Details

(Source: Self-created in Auto CAD)

Months 7-12: Steel Frame Erection

Steel column and beam construction

Typically, temporary support is provided in a structure to prevent undesired deformation.

Months 13-16: Floor Slabs

Installation of steel decking

Pounding of concrete for compound slabs

Months 17-18: Roof Structure

Roof structure installation

Completion of roof deck

Months 19-21: Bracing and Shear Walls

The systems of bracing or support that is installed

The building and installation of RC shear walls

Months 22-24: Finishing Works

Both internal and external finishes

End of lease and handover

Stability check for the design is done using the Finite Element (FE) Analysis

Proper structural design of the medical center building plays the critical role in its efficiency as well as safety from various disasters. The Finite Element (FE) analysis is then used in an attempt to confirm the design and to evaluate structural response under several loads (Cornish et al. 2023). This brief describes the methodology, results and modification based on FE analysis of the model.

FE Analysis Software

The FE analysis is therefore performed using structural analysis software known as STAAD.Pro. The software enables the development of the complete 3D model, with structural components described by beams, columns, floor slabs, and foundations. The model takes into account characteristics of the building materials and the loads applied as well as boundary conditions, and subsequently predicts the behaviour of the building based on the former factors when subjected to the latter.

Results and Comparison

To confirm the performance of the structure, the FE analysis results are compared to the manual design computations carried out to design the structure. Key parameters evaluated include:

Deflections: The analysis also determines the deflections of the beams, the floor slabs and the general structure when loads have been applied on it. These are then validated against the allowable deflection limits to determine if these conform to standard design limits.

Stresses: Stresses in the members of structure like beams and columns, under different loading situations, are determined by the software (Chen et al. 2021). They are compared with the material yield strengths in order to check if the members are overstressed.

Buckling: The analysis assesses the critical load of columns and other compression members for buckling failure. This is followed by a comparison of the results with the critical buckling loads at varied lengths to evaluate stability.

Lateral Stability: The FE analysis confirms the lateral force resistance of the building under the operating wind and seismic loads. Finally, the findings are checked against the design requirements needed for sufficient levels of lateral force resistance.

Adjustments and Optimization

According to the FE analysis results provided, changes to the design are made to improve performance of the structure. These adjustments may include:

Member Sizing: Changing trim dimensions of various structural elements refer to beam and columns to guarantee adequate strength and stability with the least possible amount of material used.

Connection Details: Optimizing the joining interfaces to enhance contact pressure and equally distribute the loads in order to avoid high stress concentrations.

Bracing Systems: Modifying the dimensions and positions of the bracing systems to improve lateral strength and stiffness to the wind and seismic loads (Marzari et al. 2021).

Foundation Design: Amending the substructure which encompasses the loads to drawing appropriate and proper bearing for them in the building.

Conclusion

Specifying the medical center building construction as steel frame with composite floors recommended during the desk research has proved to be viable and desirable. The design calculations also the concept structural arrangement, an appropriate plan on how to construct this shape safely and then the completion of the check on the stability of this structure using finite element analysis all prove the soundness of the above propose solution. The benefits of the steel frame concept include the following: time saving, bearing capacity, extensibility if the need arises in future, and minimum use of carbon. The system’s quality compliance with the most recent Eurocodes, and taking the time to analyze and consider environmental, economic and social effects enhance the project’s sustainability and lifetime. Altogether the investigation of this topic contributes towards the successful implementation of the medical center building in satisfying the client expectations, challenges as well as setting standards for future constructions of healthcare facilities.

Reference List

Journals

- Watson, J.L., Juergens, D., Bennett, N.R., Trippe, B.L., Yim, J., Eisenach, H.E., Ahern, W., Borst, A.J., Ragotte, R.J., Milles, L.F. and Wicky, B.I., 2023. De novo design of protein structure and function with RFdiffusion. Nature, 620(7976), pp.1089-1100.

- Cao, L., Coventry, B., Goreshnik, I., Huang, B., Sheffler, W., Park, J.S., Jude, K.M., Marković, I., Kadam, R.U., Verschueren, K.H. and Verstraete, K., 2022. Design of protein-binding proteins from the target structure alone. Nature, 605(7910), pp.551-560.

- Ingraham, J.B., Baranov, M., Costello, Z., Barber, K.W., Wang, W., Ismail, A., Frappier, V., Lord, D.M., Ng-Thow-Hing, C., Van Vlack, E.R. and Tie, S., 2023. Illuminating protein space with a programmable generative model. Nature, 623(7989), pp.1070-1078.

- Jiao, K., Xuan, J., Du, Q., Bao, Z., Xie, B., Wang, B., Zhao, Y., Fan, L., Wang, H., Hou, Z. and Huo, S., 2021. Designing the next generation of proton-exchange membrane fuel cells. Nature, 595(7867), pp.361-369.

- Yeh, A.H.W., Norn, C., Kipnis, Y., Tischer, D., Pellock, S.J., Evans, D., Ma, P., Lee, G.R., Zhang, J.Z., Anishchenko, I. and Coventry, B., 2023. De novo design of luciferases using deep learning. Nature, 614(7949), pp.774-780.

- Cabeza, L.F., Boquera, L., Chàfer, M. and Vérez, D., 2021. Embodied energy and embodied carbon of structural building materials: Worldwide progress and barriers through literature map analysis. Energy and Buildings, 231, p.110612.

- Pan, Y. and Zhang, L., 2023. Integrating BIM and AI for smart construction management: Current status and future directions. Archives of Computational Methods in Engineering, 30(2), pp.1081-1110.

- Bugnot, A.B., Mayer-Pinto, M., Airoldi, L., Heery, E.C., Johnston, E.L., Critchley, L.P., Strain, E.M.A., Morris, R.L., Loke, L.H.L., Bishop, M.J. and Sheehan, E.V., 2021. Current and projected global extent of marine built structures. Nature Sustainability, 4(1), pp.33-41.

- Cornish, F., Breton, N., Moreno-Tabarez, U., Delgado, J., Rua, M., de-Graft Aikins, A. and Hodgetts, D., 2023. Participatory action research. Nature Reviews Methods Primers, 3(1), p.34.

- Chen, R., Wang, Y., Ma, Y., Mal, A., Gao, X.Y., Gao, L., Qiao, L., Li, X.B., Wu, L.Z. and Wang, C., 2021. Rational design of isostructural 2D porphyrin-based covalent organic frameworks for tunable photocatalytic hydrogen evolution. Nature Communications, 12(1), p.1354.

- Marzari, N., Ferretti, A. and Wolverton, C., 2021. Electronic-structure methods for materials design. Nature materials, 20(6), pp.736-749.

- Agirre, J., Atanasova, M., Bagdonas, H., Ballard, C.B., Baslé, A., Beilsten-Edmands, J., Borges, R.J., Brown, D.G., Burgos-Mármol, J.J., Berrisford, J.M. and Bond, P.S., 2023. The CCP4 suite: integrative software for macromolecular crystallography. Acta Crystallographica Section D: Structural Biology, 79(6), pp.449-461.

- Douaud, G., Lee, S., Alfaro-Almagro, F., Arthofer, C., Wang, C., McCarthy, P., Lange, F., Andersson, J.L., Griffanti, L., Duff, E. and Jbabdi, S., 2022. SARS-CoV-2 is associated with changes in brain structure in UK Biobank. Nature, 604(7907), pp.697-707.

- Gebauer, N.W., Gastegger, M., Hessmann, S.S., Müller, K.R. and Schütt, K.T., 2022. Inverse design of 3d molecular structures with conditional generative neural networks. Nature communications, 13(1), p.973.

- Millen, G.C., Arnold, R., Cazier, J.B., Curley, H., Feltbower, R.G., Gamble, A., Glaser, A.W., Grundy, R.G., Lee, L.Y., McCabe, M.G. and Phillips, R.S., 2021. Severity of COVID-19 in children with cancer: report from the United Kingdom Paediatric Coronavirus Cancer Monitoring Project. British journal of cancer, 124(4), pp.754-759.