Introduction - Project equipment design Assignment Sample

The target of the considering separation unit related to the production of vinyl acetate monomer or VAM and acetic acid is to separate efficiently acetic acid from a, a binary solution of acetic acid, VAM and water with a purity level of 98 percent. This design uses the principles of thermodynamics, material characterization, mechanical and energy equations as well as inherent safety measures for the best performance of distillation with specific conditions under which the process runs efficiently.

Chemical Design and Thermo Chemical Calculations

The chemical design of the separation unit is therefore centered on how best to separate acetic acid from a mixture of acetic acid, vinyl acetate monomer VAM and water in a manner that gives 98 percent purity of acetic acid. The type of distillation column is determined by the relative volatility of the components, which implies that simple distillation is satisfactory. The column is designed to run at atmospheric pressure as the VAM is prone to decomposition, the feed thus enters the column pre-heated to the bubble point with approx 75°C to increase vaporization.

Phase equilibrium between the acetic acid, VAM and water is evaluated using the Non Random Two Liquid or NRTL model to incorporate the non-ideal behavior of the system (Briand et al. 2023). In the feed mixture, 69 percent is acetic acid, 25 percent is VAM, and 6 percent is water, and the desired bottom product contains 98 percent of the acetic acid.

The operation conditions are a top product concentration of 70 percent, and the reflux ratio of 4.5 which is mainly 1.5 times more than Rmin = 3. The column is designed with fifteen theoretical stages and twenty two actual stages when tray efficiency is taken as seventy percent. The reboiler supplies the heat duty which enables separation of the acetic acid while the condenser recovers the VAM and water in azeotropic fashion (Yun et al. 2022). These parameters are measured and controlled using some temperature and pressure sensors installed at appropriate positions as the system achieves steady-state conditions to allow the desired separation efficiency.

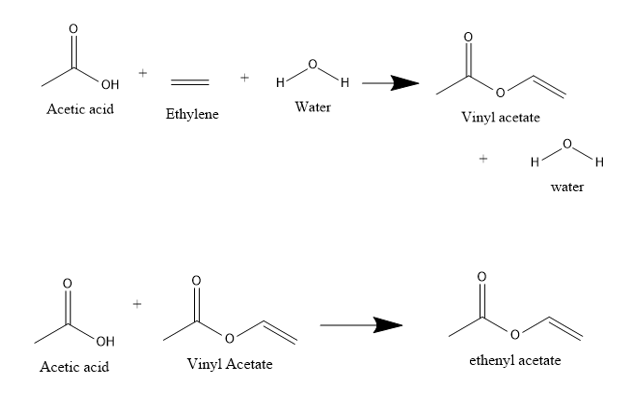

Acetic acid transformation + Vinyl Acetate Monomer = Vinyl Acetate or VAM.

The specific Vinyl Acetate monomer or VAM’s IUPAC is ethenyl acetate.

Figure 1: Product formation of Acetic acid and Vinyl Acetate

(Source: Self-created in ChemDraw)

This reaction controls the separation process and so conditions of the column have to be arranged to suit this.

Size calculation

The size of the separation unit varies with its height and diameter and depends on the separation factor, feed flow rate and operating conditions in the distillation column.

The specific type of Input Data are mainly given below.

- Feed: 15 t/h with 69 percent acetic acid, 25 percent VAM and 6 percent water.

- Target: 98 percent acetic acid recovery.

- Pressure of the Column: Atmospheric.

- Reflux Ratio or R=1.5×Rmin.

- Theoretical Stages Number: Utilizing the method of McCabe-Thiele along with equilibrium data, the total theoretical stages number or N is determined. So here mainly assuming which are given below.

Rmin=3 and R=4.5R = 4.5, N≈15.

- Actual type of Stages: With a specific tray effectiveness of 70 percent, Nactual=N/0.7=22.

- Column Diameter: Vapor traffic along with flooding type velocity specifically determine the overall diameter. Utilizing the equation of the design which are given below.

D= √ 4.Qv/π.u

Here mainly assuming a specific vapor load or Qv and permissible velocity or u, the overall diameter is mainly approximately 1.2 m. - Height of the Column:

Stage height = 0.6 m.

Total height = Nactual × Stage height+Allowance ≈ 16m.

So the particular final Size of the Diameter is 1.2 m and Height equals 16 m.

Material for manufacturing

This means that the material chosen for the fabrication of the distillation unit must easily resist attack from chemicals used in the process, withstand high temperatures and must possess reasonable mechanical properties under working conditions. This process requires operation with acetic acid, vinyl acetate monomer and water, and therefore requires a material resistant to acidic and mild oxidation.

The best choice of stainless steel is austenitic, particularly the SS316L type. It has a layer of corrosion resistance to acetic acid and other organic acids at up to high temperatures so it requires low operational maintenance (Samaro et al. 2021). SS316L also offers good high temperature stability, thus useful in applications at working temperatures between 75°C to 120°C. Moreover, it has high tensile strength and benefits from good toughness so as to cater for mechanical loadings due to pressure and thermal variations during performance.

They include such as Hastelloy C-276 which can be used for a more aggressive environment or higher concentrations of acid but they are so expensive. A carbon steel with an epoxy coating may be acceptable in terms of cost. On the other hand, its life expectancy is short due to the possibility of epoxy failure or Qu. For sealing of the components, PTFE type gaskets are mainly suggested to be used since they are chemically nonreactive with the material under the operating pressure should maintain a suitable seal.

Energy Balance

Energy inventory in the distillation unit for the consideration involves the heat supplied to the reboiler, the heat rejected at the condenser and heat content of the feed stream (Carmona and Lopera, 2022). If the system is in steady state condition, it is mandatory that energy delivered along with the energy carried by the system must be equal.

- Feed Enthalpy or Qfeed: The specific type of feed is mainly preheated towards its point of bubble with approximate 75°C. Here mainly assuming a specific type of heat capacity or Cp of 2.5 kJ/kg·K for the value of 15 t/h feed which is given below.

Qfeed = mfeed⋅Cp⋅ΔT= 15,000 * 2.5 * (75−25)= 1,875,000 kJ/h. - Reboiler Duty or Qreb: The specific type of heat is mainly added to mainly vaporize the overall acetic acid along with VAM. Utilizing approximate latent type of heats which are given below.

Qreb≈3,200,000 kJ/h.

- Condenser Duty or Qcond: Condenses type of vapor at the top of the column. For specific energy balance,

Qcond ≈ Qreb−Qfeed= 1,325,000 kJ/h.

So the summary of the energy balance is mainly given below.

- Feed heating is equal to 1,875,000 kJ/h.

- Reboiler duty is equal to 3,200,000 kJ/h.

- Condenser duty is equal to 1,325,000 kJ/h

The overall unit specifically operates with the flows of balanced energy that determine effective type separation.

Mechanical Design

It is important to consider the safe and efficient mechanical design of a distillation column through the following features. The column is vertically designed so as to ensure an effective mass transfer rate of vapor and liquid (Xin et al. 2022). This orientation lets the vaper rise on its own while the liquid goes down which promotes separation effectively.

Regarding the shell thickness, Specification Software that ASME Boiler and Pressure Vessel Code is followed. The thickness required can therefore be established from the internal pressure required, the diameter of the column desired and the strength of material intended. This ensures the column can handle the pressures resultant from the operation of the pipeline hence the operating pressure. Torispherical heads are chosen for the top as well as bottom of the column. These heads are suitable for piping working conditions in terms of pressure and vacuum, strength and durability.

The column is stabilised by a skirt support structure which is designed to be fixed to the ground in order to reduce oscillations (Hadian et al. 2021). This support is designed using a carbon with epoxy coating to prevent the rates of corrosion.

For internals, sieve trays are selected because of their low cost and the fact that they provide for maximum contact of the vapor phase with the liquid phase so that separation is good. The tray spacing of 0.6 meters is maintained to provide adequate residence time for the liquid. For the same reason that the column does not necessitate mixing, it does not contain an impeller as part of its construction. Such a configuration guarantees stable performance, proper separation, and long-term working endurance.

Figure: Distillation columns with internal components such as trays, heads, and column shell

Process and Instrumental or P&ID Diagram

This paper seeks to propose a Process and Instrumentation Diagram (P&ID) for the distillation unit effectively and safely through the application of inherent safety. The feed stream, acetic acid; vinyl acetate monomer or VAM, and water are supplied into the column through flow meter & pressure control valve (Ebrahimi et al. 2024). Both of these instruments keep constant flow rate at 15 t/h and control pressure. Temperature and pressure indicators are installed within the distillation column housing sieve trays in carrying out the temperature and pressure regulation in different stages.

Experience stress-free academics with our reliable UK Assignment Help team! We combine expertise, dedication, and timely delivery to ensure your complete satisfaction and academic growth.

These bodies reboil and hence require the necessary heat for vaporization and are connected to a steam valve. A pressure relief valve is installed inside the reboiler so as to avoid conditions of very high pressure. The condenser that cools the above vapor and condenses VAM and water contains a flow control valve through which cooling water flows in order to facilitate heat exchange.

Two specific types of product outlets are mainly provided in which one column is for purified acetic acid bottoms and the other for the VAM-water azeotrope top product. Both are fixed with level controls and are connected differently; one is connected to one storage tank and the other is connected to another storage tank (Feuerpfeil et al. 2021). To meet reliability, monitoring and alarms, block valve operation, pressure relief valves and high-temperature interlocks and ESD systems and automatic venting are incorporated to avoid dangerous situations, so that it functions on the principles of inherent safety.

Figure: Elegant design to bolster inherent safety

Technical Equipment sheet

| Parameter | Specification |

| Equipment Name | Distillation Column |

| Process Description | Acetic Acid separation with 98 percent recovery from specifically Vinyl Acetate Monomer along with water. |

| Feed Composition | Acetic Acid with 69 percent and Vinyl Acetate Monomer with 25 percent, Water with 6 percent. |

| Feed Flow Rate | 15 t/h or 15,000 kg/h. |

| Operating Pressure | Atmospheric with 1 bar. |

| Operating Temperature | Bottom with the value of 120°C and Top with 75°C. |

| Column Height | 16 m that involves trays along with allowances. |

| Column Diameter | 1.2 m |

| Number of Theoretical Stages | 15 (22 actual with the value of 70 percent tray efficiency). |

| Reflux Ratio | 4.5 |

| Material of Construction | SS316L or Austenitic Stainless Steel. |

| Tray Type | Sieve type Trays with a particular spacing of 0.6 m. |

| Reboiler Duty | 3,200,000 kJ/h with the specific heat source of Steam. |

| Condenser Duty | 1,325,000 kJ/h with Cooling water as specific utility. |

| Gaskets | PTFE (Teflon). |

| Supports | Skirt support for vertical type installation. |

| Safety Features | Pressure relief type valve, temperature interlocks, along with automated type of control system. |

Cost Estimation

To calculate the cost of the separation unit using the factorial method, we need to consider direct and indirect costs.

Direct Costs:

- Cost of Purchased Equipment or PEC: This mainly includes the overall cost of the specific distillation column, reboiler, condenser, pumps, valves, along with other specific type components (Abdel-Wakil et al. 2023). Here mainly assume a specific total PEC value of 1,000,000 Dollars.

- Cost of Installation: Typically, the overall cost of installation is about 40 percent of the PEC. So the installation cost is mainly given below.

Cost of Installation = 0.40×1,000,000 = 400,000.

Indirect type of Costs are given below.

- Engineering and Supervision: This approximately 15 percent of the direct type of cost. So the calculations are given below (Ma et al. 2024).

Engineering Cost = 0.15×1,400,000 = 210,000 - Contingency: This approximately 10 percent of the total amount of costs which are given below.

Contingency = 0.10×1,610,000=161,000

Total Estimated Cost is mainly given below.

Total Cost = 1,000,000+400,000+210,000+161,000 = 1,771,000.

Conclusion

Here mainly conclude that this is facilitated by the chemical and mechanical design of the separation unit, which is tailored to provide efficient capture of the product at the required purity while at the same time operating safely and efficiently. This demonstrates that flexibility, type of material used, as well as the energy balance calculations of the unit can meet operation needs, while the inclusion of inherent safety features ensures process robustness. The cost estimation presents the direct and indirect costs of the project in detail so that the financial estimation of the project is clearly devised.

Reference List

Journals

- Abdel-Wakil, W.S., Salama, T.M., Kamoun, E.A., Ahmed, F.A.E.H., Hassan, W., El-Badry, Y.A. and Fahmy, A., 2023. Waterborne nano-emulsions of polyvinyl acetate-polyurethane coatings containing different types of vinyl monomers: synthesis and characterization. Pigment & Resin Technology, 52(1), pp.7-18.

- Briand, A., Leybros, A., Doucet, O., Ruiz, J.C., Fontaine-Giraud, P., Liotaud, L. and Grandjean, A., 2023. Versatility assessment of supercritical CO2 delamination for photovoltaic modules with ethylene-vinyl acetate, polyolefin or ethylene methacrylic acid ionomer as encapsulating polymer. Journal of Cleaner Production, 410, p.137292.

- Carmona, A.R. and Lopera, H.A.C., 2022. A new composite made from Luffa Cylindrica and ethylene vinyl acetate (EVA): Mechanical and structural characterization for its use as Mouthguard (MG). Journal of the Mechanical Behavior of Biomedical Materials, 126, p.105064.

- Ebrahimi, F., Xu, H., Fuenmayor, E. and Major, I., 2024. Material compatibility and processing challenges in droplet deposition modelling additive manufacturing: A study on pharmaceutical excipients Polyvinylpyrrolidone/vinyl acetate (PVP/VA) and Polycaprolactone (PCL). European Journal of Pharmaceutical Sciences, 200, p.106850.

- Feuerpfeil, A., Drache, M., Jantke, L.A., Melchin, T., Rodríguez-Fernández, J. and Beuermann, S., 2021. Modeling Semi-Batch Vinyl Acetate Polymerization Processes. Industrial & Engineering Chemistry Research, 60(50), pp.18256-18267.

- Hadian, A., Koch, L., Koberg, P., Sarraf, F., Liersch, A., Sebastian, T. and Clemens, F., 2021. Material extrusion based additive manufacturing of large zirconia structures using filaments with ethylene vinyl acetate based binder composition. Additive Manufacturing, 47, p.102227.

- He, Y., Zhang, Z., Ke, H. and Lu, Y., 2023. Microflow system for controlled synthesis of ethylene-vinyl acetate copolymers: Continuous copolymerization and kinetic study. Chemical Engineering Journal, 470, p.143940.

- Ma, X., Wei, H. and Luo, Z., 2024. Development and prospect of the acetylene production chain based on the process systems engineering: a focus on the polyvinyl chloride production. Reviews in Chemical Engineering, 40(8), pp.917-949.

- Qu, M., Fang, J., Mu, C., Li, Y., Huang, S., Han, L., Hiemer, S., Xu, W. and Qin, Y., 2022. A novel study on the sandwich‐structure strain sensor using ethylene‐vinyl acetate‐based hot‐melt adhesive mesh web: Fabrication, properties, and modeling. Journal of Applied Polymer Science, 139(48), p.e53209.

- Samaro, A., Shaqour, B., Goudarzi, N.M., Ghijs, M., Cardon, L., Boone, M.N., Verleije, B., Beyers, K., Vanhoorne, V., Cos, P. and Vervaet, C., 2021. Can filaments, pellets and powder be used as feedstock to produce highly drug-loaded ethylene-vinyl acetate 3D printed tablets using extrusion-based additive manufacturing?. International Journal of Pharmaceutics, 607, p.120922.

- Xin, H., Li, Y. and Peng, Q., 2022. Trans-polyisoprene/poly (Ethylene-co-vinyl acetate) polymer composites as high-performance triple shape memory materials. Polymers, 14(24), p.5344.

- Yun, J.H., Yang, J.H., Nam, J.W., Hong, J.S., Kim, H.S. and Ahn, K.H., 2022. Fabrication of poly (ethylene-co-vinyl acetate)(EVA)/biomass composite using residual Chlorella biomass through a sequential biorefinery process. Materials Today Sustainability, 18, p.100142.