- Review On Traditional & Modern Supply Chain Management Assignment

- Introduction of Rice Supply Chain Management

- Research aim & objectives

- Importance of rice supply chain and its model

- Model and implementation of the rice supply chain

- Role of technology and collaborative model in improving the supply chain model

- Comparison of the traditional supply chain model with the modern one in the UK

- Theoretical perspective

- Methodology

Review On Traditional & Modern Supply Chain Management Assignment

Introduction of Rice Supply Chain Management

The role of supply chain management is to manage the flow of goods and services that are involved in the process of transforming raw materials into the final product. This study is focus on understanding the role of the modern rice supply chain and explains it with Koolmill Ltd. It is considered the most important aspect of the production process as it decides the quality of a product. There is a scope for improvement in the supply chain management of the UK as business uncertainty is increasing due to the high rate of inflation which is 8.8%. In the UK the ripple effect can be noticed which increases the operation cost of the supply chain due to high inflation. An impact is been noticed on the price and productivity that accommodate products including rice.

Link to a reliable source for assignment help in the UK — New Assignment Help — to enhance your academic performance.

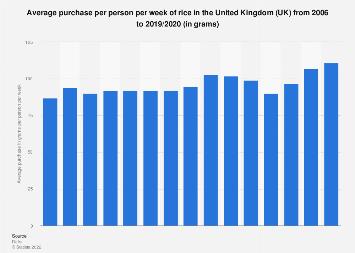

Figure 1: Rice supply chain in the UK

(Source: Statista, 2022)

The above figure shows the consumption of the rice supply chain in the UK. It is shown that a 12% consumption in the year 2006 whereas in the year 2207 a consumption increases up to 13%. In the years 2014 and 2015, consumption is the same but in the year 2019 consumption increased by up to 15%. The supply chain maintains the quality of the product; it also helps to identify the correct set of raw materials to avoid mistakes. The supply chain of rice in the UK is not that favourable, unlike other Asian countries the consumption of rice is 5. 6 kg per year and a normal citizen consumes only 23 grams of rice. Thus it can be seen that the supply chain of rice needs to be improved so that its demand increases.

Project purpose

The study's aim is to review traditional and modern rice supply chain management in the UK ". A traditional supply chain has followed a framework of SCM following a "multi-stage system of the supply chain". The supply chain network helps a company minimize the cost of consumer demands and provides equipment to play a role in the development of the supply chain in traditional and modern management. This study helps to manage a relationship between businesses responsible for an efficient amount of production. It will also focus on why the supply chain is one of the core aspects of running a business. The study is going to illustrate how the supply chain has evolved from a traditional approach to a modern approach (Agrawal and Narain, 2018). It also wants to focus on understanding the relationship between the supply chain and commodity products. The traditional supply chain focuses on the provision and production of materials however the modern supply chain focuses on the needs of customers. For example, Kool Ltd focuses on the preferences of the customers as they follow the modern supply chain model. The purpose of this project is to discuss the possibilities of growth in terms of managing the supply chain. A personal view is gathering knowledge for a supply chain that works is evolved in the model of the supply chain. The importance of the involvement of stakeholders in supply chain management will be discussed with the help of theory.

Research Place

In this proposal, Koolmill rice Production Company is considered. As the company operates in the UK thus the research place will be the UK and all the information regarding the rice supply chain management will be based in the UK.

Research aim & objectives

Research aim

This paper aims to investigate the traditional rice supply chain and modern rice supply chain in KoolMill Ltd. in the UK.

Research objective

- Determining a traditional method is helpful for Koolmill Ltd. in enhancing a modern supply chain.

- To understand the importance of an effective supply chain for modern rice supply chain in Koolmill Ltd. in the UK.

- To investigate the role of technology in improving the supply chain model

- To compare the modern Supply chain model with the traditional method in the UK

Literature review

Importance of rice supply chain and its model

The role of the supply chain is immense in terms of maintaining the commodity products. A Koolmill Ltd. Is been affordability that maintains a supply chain and also focuses on accessibility. It is noted that a commodity amount of products is been dependable on various activities of a supply chain. As per the view of Abdul-Rahaman (2018), rice is consumed in over 180 countries in the world and is dietary a staple for a more amount of people for the food. It is noted that the cultivation of rice is utilized for agriculture and approx 1 million households depend on the cultivation of primary resources of the environment. Contrary to Abdulai (2018), around 2.5% of a human has induced GHG emission for cultivating rice is comparable to international aviation. Koolmill Ltd. strives to transform an outdated by delivering a modern type of ultra power and enhancing sustainable types of approaches to processing. A vision is to change antiquated types of wasteful products in the industry feeding over 3 billion people into fuel poverty.

Reduction of operating cost

If the supply chain works efficiently the retailer can get their delivery on time, thus they don't have to spend much on inventory charges. In terms of perishable items, the cost of inventory is high thus it gets reduced if the supply chain can ensure faster delivery (Esmaeilian et al., 2020). Koolmill Ltd. is focused on a retrofit of small manufacturing enterprises and is offering a 95% saving power that supports a down time with a support proactive type of monitoring. The manufacturer and retailer plan for a network that can meet customer service goals.

Financial improvement

The leverage of profit will increase as it helps to control and decrease the supply chain cost. If the cost of the supply chain will decrease then the profit of the organization can increase. It decreases the value of the fixed assets as a proper supply chain reduces the use of plants, vehicles for transportation, and warehouses (Alfarsi, Lemke & Yang, 2019). As the flow of delivering products to the customers increases the flow of cash also increases.

Improvement in customer service

It has been observed that customer service can be boosted by achieving sustainability in the supply chain of the management system. Therefore, it has been observed that approximately 2.5% global rate of GHG emissions has been taking place due to the supply chain intervention of rice. The Koolmill has a major focus to achieve sustainability through a modern and sustainable cereal processing approach. It has been observed that nearly 1.5 million high-performance types of machinery in contrast to the SME millers have been developed by the concerned organization for the betterment of customer service.

Along with that "Smart milling technology" has been designed by Koolmill to prevent rice waste and 30% of rice waste has been reduced to 2%. Besides that, types of machinery developed based on 'cool' milling technology have a huge advantage in terms of nearly 90% less energy consumption. On the other hand, customer service has been profoundly improved by the concerned organization through initiating an affordability business model thus customers have to pay for the used mill amount only. The smallholders of the value chain of rice have been rebalanced with the perspective of fair price thus a huge competitive advantage has been gained by customers.

Model and implementation of the rice supply chain

As per a view of Jamaludin (2022) maintaining the supply chain can be a solution for rice farming agriculture. The supply chain of rice is comparatively different from other products. In the case of the rice supply chain, the primary stage is held by the rice farmers thereafter the raw material is handed over to the processing companies. Contrary to Nugraha (2022) In Kool, mill Ltd. rice is produced in such a way that it can be cooked in a microwave. It was possible due to the implications of modern technology and to enhance accessibility. The model in the rice supply chain suggests that all the products should be done based on the preference of the individuals.

The main motive of this model is to prioritize the stakeholders of the company. In the UK the demand for rice is limited, thus the model suggests certain steps that can provide better services to increase the rice demand. The supply chain can vastly impact the revenue generation for a product, thus if the model is used in a significant way its demand can be increased (Purwandoko & Seminar, 2019). In the UK over £45.2M of rice is been imported which shows that the UK is highly dependable on outsiders for importing rice. Thus it is essential to maintain the supply chain more consciously as international trade is involved.

Role of technology and collaborative model in improving the supply chain model

Role of technology are as follows:

Better control over the production process

In the case of supply chain management information technology is used for improving the efficiency of operations. Implementation of technology helps to improve transparency and it helps the manufacturing company to get better control of the flow of products (Fatorachian & Kazemi, 2021). The role of accountability and better visibility in operation is needed. Task management is an example of a collaborative type of model is having various types of an operation that handling with a proper amount of planning.

Improvement in inventory management

According to Dey (2021), is stated that process streamlining is following a tracking process and distribution in the industry. It provides an advantage of the technology of SCM to decrease cost, improve consumer service, and increase operational types of efficiency. Contrary to Modgil (2021), a transformation system of management is to organize and consolidate levels for a TMS system into a shipment document and in the management tools.

Effective order tracking

Tracking the order increases transparency, it also allows businesses to overcome the issues of loss of packages, and discrepancy also gets reduced. CRM and WMS software is used for tracking the orders. This allows the organization to get a detailed review of the stage of orders and also gets an estimation of when they will get delivered.

Increase collaboration

Effective communication helps to increase collaboration between retailers and suppliers. If communication remains active between suppliers and retailers then it can help the organization to get a better hold of products and commodities. Technology helps to run a centralized communication and the level of visibility also increases which avoids miscommunication.

The collaboration model mainly describes the communication done between different individuals for the continuation of an operation. The process supports interaction and innovation at the same time. Supply chain management requires a model of collaboration so that the interaction between customers and sellers remains positive (Kivlichan et al., 2021). It also focuses on building communication between suppliers and retailers. Data analytics is helpful to Koolmill Ltd. in the progress of the supply chain and a collection of shipments that is a benefit for decision-making in a large number of shippers. The digitally enabled logistics types of providers are transformed to offering digital types of platforms for shipment analytics and tracking information effectively.

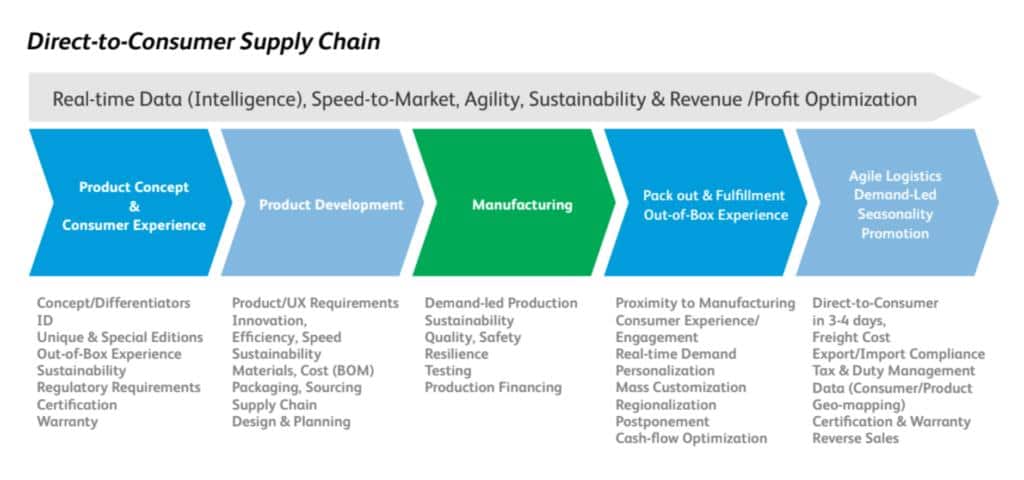

Comparison of the traditional supply chain model with the modern one in the UK

In this proposal, the purpose of the project is to discuss the difference between the traditional supply chain and the current supply chain. According to Rejeb (2019), Modern supply chain management focuses on customer demand and preferences. For instance, consumer product company Kool Ltd focuses on improving the quality of the rice they provide. Contrary to Keogh (2019), this helps to increase revenue as higher customer satisfaction helps to create better product value. However, in the case of the traditional supply chain, the focus remains on the provision and production process (Kivlichan et al. 2021). As a result, it can create drawbacks. For instance, an organization is focusing on production and is unaware of the demand for the product in the market. Then it might happen that the production unit might end up producing more units than required which leads to wastage.

A modern supply chain enables a business to create new paths for collaboration with other companies. However, the traditional supply chain focuses on a single path and the rate of flexibility is less. In modern SCM the value of the product is prioritised so that the customers can get a better experience (Rejeb, Keogh, & Treiblmaier, 2019). However, in traditional SCM, no such value is viewed and the main focus is the production unit.

Modern SCM implements the latest technologies as a result the rate of scalability is much higher. It helps to increase its portfolio value in front of the customers which increases its goodwill (Muller, 2019). Traditional SCM cannot provide so many factors as a result the company cannot remain flexible and also creates many restrictions for expansion. The UK ranks between 4th to 7th in the world in terms of technology. Thus, most companies use modern SCM so that scope of expansion remains flexible.

Theoretical perspective

Stakeholder management theory related to supply chain management

Stakeholder theory represents the view of capitalism and also shows the relationship between customers and the business. Stakeholder means people that are involved with the company or the product such as employees, customers, suppliers, investors and communities. Stakeholder theory helps to understand the functions of the supply chain more deeply. Stakeholders are the prime member of maintaining the supply chain management such as suppliers and buyers. The model also suggests focusing on the stakeholders rather than only focusing on the shareholders. This increases the ability of the company to retain valuable members for a longer period of time.

The stakeholder model also focuses on maintaining the profitability of the organization by ensuring better operation. The main focus is to prioritize the members of the company such as its employees and customers. In the case of the supply chain if all the members get proper behaviour, then internal communication will improve. If the relationship with suppliers is good then the availability of raw materials can be ensured with competitive prices. Thus, it can be seen that the model of stakeholders is interrelated to that of supply chain management.

Translation cost theory

This theory helps to understand the agencies from the government. It helps to break down the internal and external transactions and their impact on the economy. The four types of TC are opportunity cost, enforcement cost, bargaining cost and search cost. It helps to identify the value of transactions that had taken place during any supply chain activities. These transactions are later analysed to highlight any type of mistake that might take place. Thus, the transaction cost model is essential for SCM.

Methodology

Place

It has been observed that modern technology data regarding the concerned topic have to be collected from Koolmill Ltd. However, a basic reflection of modern technology has been accessed from the website of the concerned organization. The brief detailed data of "Smart milling technology" and "'Cool' milling technology" of the concerned organization have to be gathered from the organization. Besides that, data regarding traditional technology have to be collected from a different websites, journals, reports and news articles.

Sampling approach

It has been observed that modern technology data need to be assessed from Koolmill Ltd. and besides that traditional technology data will be collected as secondary data. Therefore, all the collected secondary data of traditional technology with respect to the concerned topic needed to be performed through the "Systematic Clustering" sampling approach. Thus, obtained data sampling will be performed through a systematic pattern of contexted elements. The elements of sample data have been decided to select regular intervals. The elements of sampling will be decided upon the different types of traditional technology with respect to sustainability over the supply chain of the concerned sector.

It has been observed that the concerned sampling approach has a major role in terms of the arrangement of obtained data through the systematic pattern (Campbell et al., 2020). Purposive sampling will be used for collecting secondary data as well. It will be purposive because appropriate keywords will be used for selecting the secondary data. Keywords such as “Supply chain”, “supply chain in rice mill”, “technology”, “traditional supply champion”, and “modern supply chain” will be used.

Accessing sample

Those data have been considered secondary data thus secondary data collection approach of research methodology has to be followed. In terms of data collection from the website, related technology-owned organization data needed to be used (Pandey & Pandey, 2021). In terms of articles, data will be collected from different sources such as "Google Scholar", "Science Direct" and Elsevier have been considered. During the collection of data with respect to the concerned topic data relevance and authenticity of the data have to be measured with a Boolean table and "Inclusion and Exclusion" criteria.

Data collection and analysis

The obtained data needed to be analyzed through the secondary data analysis approach and there will be both qualitative and quantitative data. In view of the nature of the data, thematic analysis of data will be performed thus extraction and development of themes with respect to secondary data will be developed. Thereafter, themes will be critically discussed and contrasted with respect to facts and figures obtained through the secondary data. Then, the pattern of data will be observed through the theme and need to be contrasted with the aim and objectives of the research. The primary data is will be collected for managers of Koolmill Ltd. and gathering secondary data is collected from an authentic website (Newman & Gough, 2020). It will help to identify the relevance of data and relate them to the research objectives. The topic will be selected and the data the researcher will be familiar with the data. Initial codes will be created from the data. The themes will be reviewed again and then they will be defined.

Research text

The data will be supported by a literature review. The intent will be done by the author's name and data to support the data. Justification will be given for supporting the data with appropriate in-text citations. The literal meaning and concept of the supply chain model will be described. The comparison will be done between traditional and modern supply chain processes.

References

Abdul-Rahaman, A., & Abdulai, A. (2018). Do farmer groups impact farm yield and efficiency of smallholder farmers? Evidence from rice farmers in northern Ghana. Food Policy, 81, 95-105.

Agrawal, P. and Narain, R., 2018, December. Digital supply chain management: An Overview. In IOP Conference Series: Materials Science and Engineering (Vol. 455, No. 1, p. 012074). IOP Publishing.https://iopscience.iop.org/article/10.1088/1757-899X/455/1/012074/pdf

Alfarsi, F., Lemke, F., & Yang, Y. (2019). The importance of supply chain resilience: an empirical investigation. Procedia Manufacturing, 39, 1525-1529.https://www.sciencedirect.com/science/article/pii/S2351978920303590/pdf?md5=676a49fa327d566ffa4a8fa6ea2482d0&pid=1-s2.0-S2351978920303590-main.pdf

Campbell, S., Greenwood, M., Prior, S., Shearer, T., Walkem, K., Young, S., ... & Walker, K. (2020). Purposive sampling: complex or simple? Research case examples. Journal of research in Nursing, 25(8), 652-661. https://doi.org/10.1177%2F1744987120927206

Delgado, M., & Mills, K. G. (2020). The supply chain economy: A new industry categorization for understanding innovation in services. Research policy, 49(8), 104039.https://www.hbs.edu/ris/Publication%20Files/1-s2.0-S0048733320301177-main_91317e57-9217-4a3d-9707-7f0b6034febc.pdf

Esmaeilian, B., Sarkis, J., Lewis, K., & Behdad, S. (2020). Blockchain for the future of sustainable supply chain management in Industry 4.0. Resources, Conservation and Recycling, 163, 105064.https://par.nsf.gov/servlets/purl/10175155

Fatorachian, H., & Kazemi, H. (2021). Impact of Industry 4.0 on supply chain performance. Production Planning & Control, 32(1), 63-81.

https://www.mdpi.com/1999-5903/11/7/161/pdf

Jamaludin, M., Fauzi, T., & Nugraha, D. (2021). A system dynamics approach for analyzing supply chain industry: Evidence from rice industry. Uncertain Supply Chain Management, 9(1), 217-226. http://growingscience.com/uscm/Vol9/uscm_2020_38.pdf

Kivlichan, I. D., Lin, Z., Liu, J., & Vasserman, L. (2021). Measuring and improving model-moderator collaboration using uncertainty estimation. arXiv preprint arXiv:2107.04212.https://arxiv.org/pdf/2107.04212

Kumar, A., Singh, R. K., & Modgil, S. (2020). Exploring the relationship between ICT, SCM practices and organizational performance in agri-food supply chain. Benchmarking: An International Journal.

Muller, M. (2019). Essentials of inventory management. HarperCollins Leadership. https://t.me/PrMaB

Newman, M., & Gough, D. (2020). Systematic reviews in educational research: Methodology, perspectives and application. Systematic reviews in educational research, 3-22. https://doi.org/10.1007/978-3-658-27602-7_1.

Pandey, P., & Pandey, M. M. (2021). Research methodology tools and techniques. Bridge Center. http://dspace.vnbrims.org:13000/jspui/bitstream/123456789/4666/1/RESEARCH%20METHODOLOGY%20TOOLS%20AND%20TECHNIQUES.pdf

Purwandoko, P. B., & Seminar, K. B. (2019). Development of a smart traceability system for the rice agroindustry supply chain in indonesia. Information, 10(10), 288.https://www.mdpi.com/2078-2489/10/10/288/pdf

Rejeb, A., Keogh, J. G., & Treiblmaier, H. (2019). Leveraging the internet of things and blockchain technology in supply chain management. Future Internet, 11(7), 161.

Saurabh, S., & Dey, K. (2021). Blockchain technology adoption, architecture, and sustainable agri-food supply chains. Journal of Cleaner Production, 284, 124731.

Statista.com, 2022. Rice - United Kingdom. Retrieved from: https://www.statista.com/outlook/cmo/food/bread-cereal-products/rice/united-kingdom

Suharmono, M., Alexandri, M., Sumadinata, R., & Muhyi, H. (2022). Outsourcing in supply chain: A bibliometric analysis. Uncertain Supply Chain Management, 10(4), 1501-1508. http://m.growingscience.com/uscm/Vol10/uscm_2022_59.pdf