1. Introduction - Digital Construction And Bim Assignment Sample

The utilization of construction industry can be regarded as an essential part of the contemporary world and the Burj Khalifa project as the people’s triumph and scientific progress. Standing at an amazing height, it is probably one of the tallest building to date; the Burj Khalifa could be described as a fusion of architecture and technology. This report delves into the intricacies of digital construction and Building Information Modeling (BIM) through an in-depth examination of the Burj Khalifa project. It includes the impacts of construction delay risk, the use of proactive technology integration strategy, the use of BIM on the supplier chain and the barrier that occurs during the project delivery. From these aspects, the report does hope to have made some suggestions in increasing the construction efficiency and initiate a positive attitude to construction innovation..The construction industry is considered as one of the key contributors to the contemporary structure with such wonders as Burj Khalifa standing for human achievement and technological advancement. Based on the following areas of focus, including construction delays, BIM utilization, new generations of construction technologies, the organization of supply chain, and improvement of construction outcomes on projects, this essay discusses digital construction.

2. Main Body

2.1 Delays in Construction

Delay in construction is a common problem in large complex construction projects and this is exceptionally manifesting in increased costs and substandard quality. This project also experienced different kinds of hitches during its construction phases although it has become successful at the moment. Some of the causes of delays may be due to unavailability of materials, labor disputes, unfavorable weather conditions, changes in design, and financial consideration. Similarly, lack of raw materials, for example, compromises construction schedule as some material may not be readily available as per the schedule. As with any project, there are external factors which have an influence on project performance; for example, strikes or lack of the right type of workforce will slow down progress. Seasonal conditions particularly during winter in cold climate countries become a problem to any construction work that has to be done outdoors. There is a shift in design that can be caused by a change in clients’ expectations or an alteration of the laid down regulations hence leading to rework and therefore slowing down the entire process (Sepasgozar et al., 2023). Since they can reduce the available resources that are available to the project due to poor funding or delayed payments, financial constraints have the potential to slow down the project.

Figure 1: Digital construction based on BIM

Minimizing these delays is however possible through efficient planning in the project. Scheduling is beneficial when it comes to implementing the notion of critical path segments and as such, the Critical Path Method (CPM) can be of great use. This makes it easy to identify the possibility of delays in delivering goods and services hence embracing contingency planning and risk assessment to minimize these possibilities (Adeniyi et al., 2024). Effective communication and cooperation between the various stakeholders help eliminate bottlenecks and misunderstandings due to the free, or rather smooth, and sharing of information..The construction of the Burj Khalifa faced many challenges due to the magnitude of the structure and the unique engineering solutions in building it. It is noted that one of the problems that led to the delays was the scarcity of people with skilled labor, especially those that have been trained in construction of high rise facilities that influenced crucial stages (Honghong et al.2023). Besides, problems involved in the concrete supply and use as a construction material that aims to resist high temperatures and wind pressure at operational altitude also hampered structural construction progress. A number of factors that characterized the construction industry in Dubai includes extreme weather conditions particularly in summer periods where temperatures in some months exceeded 45° celsius limited outdoor working hours and affected the construction timetable. Moreover, infectious disease affected materials where certain types of glass panels and steel reinforcement came from different countries which would inevitably lead to longer delivery times and increasing delays (Zhou et al.2024). Another problematic area was designs and changes in design, those changes in the architectural plan that were made when construction had already advanced lead to concerns with structure stability, thus halting some contractors activities until it awaited further approval. Financial constraints were also an issue, for instance, during the global financial crisis in 2008 and its negative impact on funding and doubts on its projects’ viability. This involved proper planning for time to ensure that proper time was allocated to each sector and if any emergent issues occurred the project had proper contingency plans and risk management strategies that had to be taken so as to ensure that the project achieved high levels of innovation and quality (Mayouf et al.2024). Other measures, such as utilising the critical path method or employing real time digital monitoring also reduced further disturbances and construction progress.

2.2 Technology Used in Burj Khalifa

Several key technologies were used in the construction of the Burj Khalifa project to enable it reach its great heights notwithstanding the odds. Among these, the main enabler turned out to be Building Information Modeling (BIM). BIM was very constructive in the generation of detailed models in the development of the building project. This made it for the different stakeholders in the process to identify such issues as would be the case before setting up the construction phase (Baghalzadeh Shishehgarkhaneh et al., 2022). This has fostered integration of the four dimensional between architects, engineers and contractors, making certain that the intended design was effectively implemented during construction.

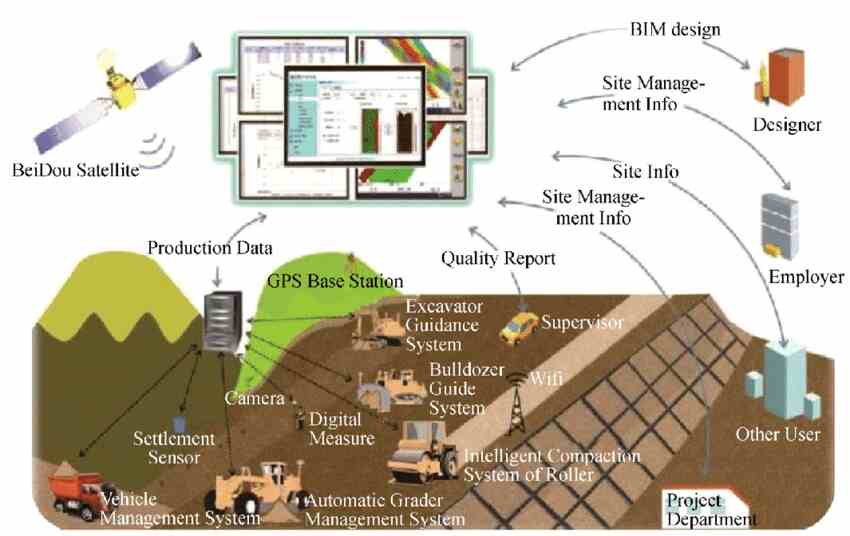

Figure 2: Intelligent Construction Technologies

Apart from BIM, Information Communication Technology (ICT) tools were employed in the project to enhance communication and data sharing. These tools ensured that information on any project that was being worked on could be shared and also updated in real-time. Project management and scheduling software, and other progressing intelligent systems helped in overseeing constructiveness and eradicating progress as well as compliance to temporal schedules (Ullah et al., 2024). These four technologies were chosen because they add more efficient, accurate and collaborative features to the project that would make it successful..Several forms of technologies were used for construction of the Burj Khalifa because of the engineering complexities encountered in the structures development (Gan et al.2021). One of these innovations was the buttressed core structural system which offered the ability to resist lateral loads and thus making it possible for the tower to be resistant towards forces such as wind forces and any forces of earthquakes. Superplasticizers and special concrete cooling methods were used in mixing concrete for the construction of this facility, to support the building’s weight in the vertical position and to reduce the thermal crack phenomenon in the region. Advanced hydraulic pumping mechanisms were used in order to pump concrete to the height of more than 600 meters wherever challenges of gravity and pressure arised (Jemal et al.2023). To enhance coordination with these stakeholders, BIM has been instrumental in the design processes that involve using digital tools, identification of clashes, and overall improvement of construction related geometries. Notably, smart sensors and real-time structural health monitoring systems were integrated to diagnose stress distribution and structural stability in the long run. The process of loosely attached curtain wall was implemented to assemble the required high-performance glass facade with insulation and energy efficiency. The efficient use of ICT tools consisting of a project management platform for cloud-based applications allowed the engineers, architects, and contractors to work efficiently, effectively, and in harmony during the implementation of the project (Gehring et al.2023). Altogether, these advancements in technology improved the overall work processes, manage risks, and guarantee the accomplishment of the biggest skyscraper in the world within the given time frame.

2.3 BIM for Supply Chain Management

It is possible to identify significant opportunities that the adoption of Building Information Modeling (BIM) can provide in the direction of supply chain management in construction projects. Through the information created in executing various phases of the project, BIM helps in the management and optimization of the supply chain. For example, by using the BIM system, one can easily track the materials from where they are purchased up to the time they are used, hence ensuring availability of the necessary resources in the project. This capability has the effect of decreasing time and minimizing the occasion of cost which would have been accrued in the process hence cuts costs and is environmentally friendly.

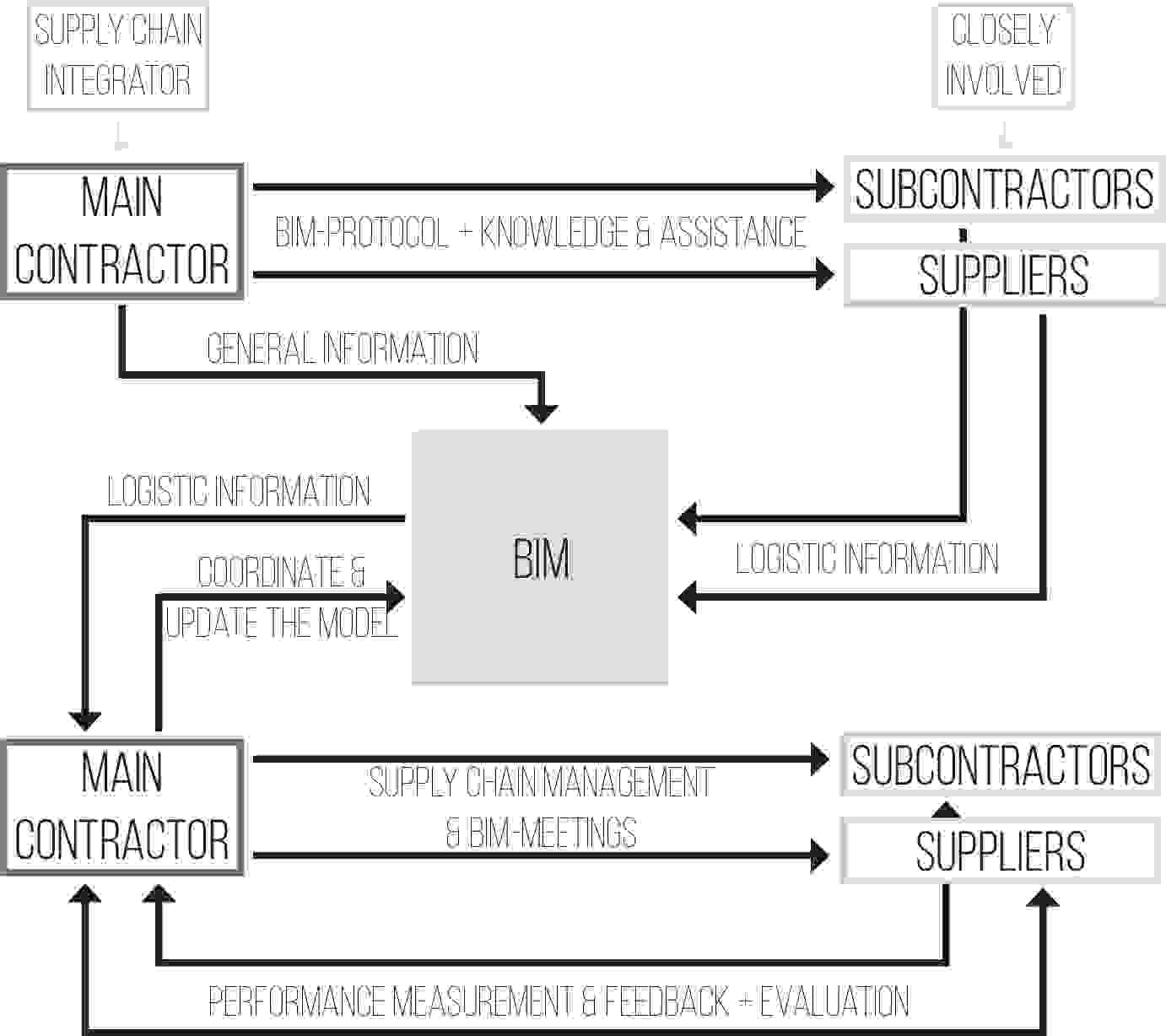

Figure 3: BIM Supply chain

Furthermore, it helps in proper coordination with the suppliers, contractors and project managers of the project. With supply chain information being incorporated in the BIM model, the stakeholders will be in a position to identify the availability of the required material, the time taken to get the material and any existing likely hitches. This information helps one to be in a position to make necessary adjustments and prevent a situation that might affect the flow of the supply chain consequently improving the efficiency of the supply chain (Disney et al., 2022). This has been made possible by the representation of the supply chain in the BIM model that is helpful in analyzing different choke points and the flow of logistics, which in return enhances the construction process..BIM has significantly enhanced the supply chain management situation in the construction industry through supply chain visibility of procurement, logistics and material (Tomczak et al.2022). Implementing BIM facilitates digital twins that assists in tracking of inventory to avoid the cases of shortages and excess inventories. This means that when delivery teams are able to connect various data sources, it is able to forecast when a particular project is likely to be delivered, thus avoiding incidences of disruptions due to scheduling issues. The use of BIM platforms that are located in the cloud means that suppliers, contractors and engineers can be able to communicate effectively and manage the procurement process in order to avert adverse issues arising from mismanagement. In the same context, RFID and IoT tracking systems incorporated into BIM make materials track ability more effective for timely supply of resources (Pan et al.2023). There are benefits that come with integrating predictive analytics on BIM models in that it helps in the prediction of demand to avoid areas that may lead to supply chain hindrances in the procurement level of goods and services. Incorporated in a built environment, BIM improves the contract visibility, hence reducing potential issues arising from delayed shipment or order discrepancy. Also, prefabrication and modular construction, which are aligned with BIM, optimize the production processes due to just in time delivery to avoid cluttering of the construction site. It is possible to consider construction sequences in BIM to make necessary risk management decisions for improving the supply chain flexibility (Deng et al.2021). In accordance with it BIM improves the supply chain by improving the flow, cost and use of resources of logistics in construction projects.

Say goodbye to sleepless nights! Our Online Assignment Help connects you with experienced writers who craft well-researched, plagiarism-free assignments tailored to your specific requirements and academic standards.

2.4 Constraints in Construction Project Management

Construction project management therefore exposes project managers to constraints such as the amount of money that is available for the project, the time within which the project must be completed and the resources available in the project. As it is evidenced by all similar big projects, these challenges were there, and Burj Khalifa could not escape them, which called for efficient planning and management of resources. Lack of adequate funds created conditions for strict cost control; at the same time, all available funds had to be spent effectively without sacrificing quality (Adel et al., 2022). The situation meant that there was a high level of compliance on the time factor; failure to observe the times meant that there was a possibility of going over budget and not being able to meet the timeline. Availability of resources such as material and people needed a strategic approach in sourcing and distribution in order to facilitate productivity in the projects underway.

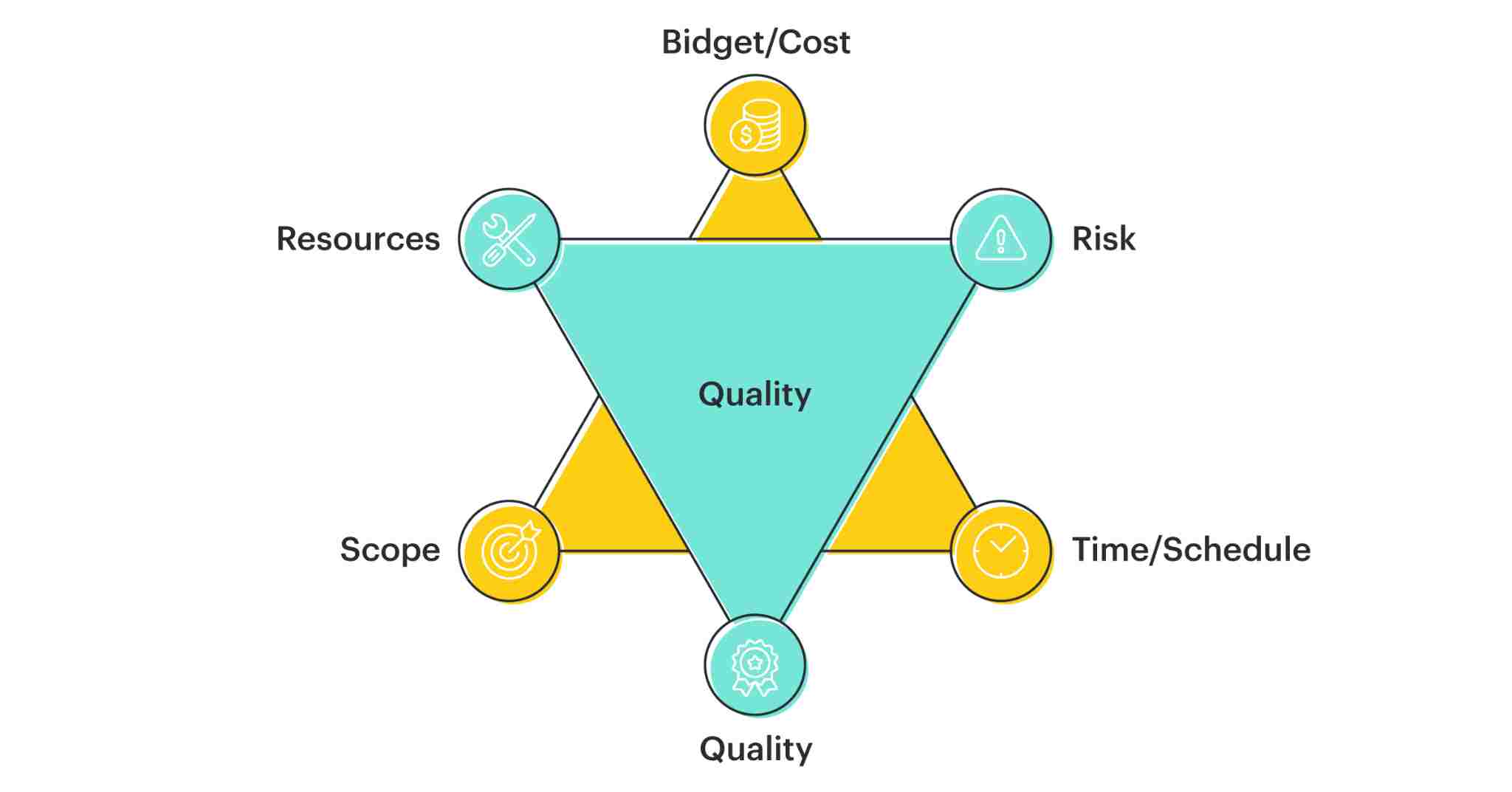

Figure 4: Managing Project Constraints

It is concerning that in spite of such constraints, Building Information Modeling (BIM) can make a difference in managing the same. Due to the sufficient quality of the representation of the project, BIM is useful for identifying potential problems and making a plan to solve them. For instance, it is possible for a BIM model to analyse the potential use of resources and estimate returns for the particular project by evaluating various possibilities. Thirdly, it enables the tracking of development progress and enables some alerts to be made early enough to meet arising difficulties (Sepasgozar et al., 2022). In this way, BIM affects the efficiency of the management of construction projects positively in the following manner.. The construction of large buildings such as the Burj Khalifa involves coping with various constraints, the most important of which are time, money and people factors (Nour El-Din et al.2022). Due to financial constraints, managers must be very careful when estimating costs, tracking the expenses, and evaluating the risks likely to cause excessive spending. Schedules in business require time because it can only be tight or time-based hence requires a lot of time to ensure that it does not end up costing too much money. Furthermore, it is observed that there are difficulties regarding the procurement of materials, lack of workforce, and other logistics that affect business continuity. The use of BIM also helped to overcome these challenges since it provides the ability to have an accurate visualization of the project, together with using analytics and automating the processes (Alnaser et al.2024). BIM also reduces the formation of design clashes since it works with clash detection techniques so that the contractor does not have to conduct costly construction works that may be interfered by such clashes. Besides, utilizing AI-driven simulations helps schedule resource use, that is, the materials and labor to ensure efficiency. The technological advancement in digital twins enables the construction managers to monitor the progress, identify the causes of delays and proactively plan on how to handle it. Effective sharing of documents removes confusion and misunderstandings that would otherwise result in costly blunders among the stakeholders. Moreover, integration of the supply chain within BIM impacts on inventory management that avoids conditions, which lead to stock out or excess inventory (Uzairuddin et al.2022). BIM provides the best solution to the management of constraints through improved cost management of projects and the most probable method of construction breakthrough, especially in a world-class building such as the Burj Khalifa.

3. Conclusion and Recommendations

This raises the Burj Khalifa project as an example of how digital construction and BIM can address the threats and fears in the field and deliver great results. Through the use of effective technologies and other efficient methods of project management, the project team was able to overcome time challenges, resource constraints in order to ensure the construction of the iconic skyscraper. In this project, certain lessons were learned that necessitate the drive towards change and cooperation in any construction related setting. In future projects, it is suggested that the stakeholders should incorporate the use of BIM and ICT technology to improve efficiency and coordination. Thus, with regards to the above reasons for project delay, there is a need to enhance the promotion of proactive risk management and communication as keys to enhancing the enhanced outcomes of; in incorporating these measures, the construction industry will be in a position to provide mankind with innovative prospects of developing better structures that can support future generations..The case of Burj Khalifa effectively depicts how new-age digital technologies and BIM can reduce time constraints and other issues related to construction and availability of resources required for construction. In that procedure real-time data analytics of such a system together with AI and IoT make coordination better, reduce errors, as well as optimizing the system. In subsequent constructions, advanced and sophisticated technologies need to be incorporated to design postmodern buildings that are sustainable, safe, and futuristic.

Reference List

Journals

- Sepasgozar, S.M., Khan, A.A., Smith, K., Romero, J.G., Shen, X., Shirowzhan, S., Li, H. and Tahmasebinia, F., 2023. BIM and digital twin for developing convergence technologies as future of digital construction. Buildings, 13(2), p.441.

- Adeniyi, O., Thurairajah, N. and Leo-Olagbaye, F., 2024. Rethinking digital construction: A study of BIM uptake capability in BIM infant construction industries. Construction Innovation, 24(2), pp.584-605.

- Ullah, H., Zhang, H., Huang, B. and Gong, Y., 2024. BIM-based digital construction strategies to evaluate carbon emissions in green prefabricated buildings. Buildings, 14(6), p.1689.

- Disney, O., Johansson, M., Leto, A.D., Roupé, M., Sundquist, V. and Gustafsson, M., 2022. Total BIM project: The future of a digital construction process. Industry4. 0 Applications for Full Lifecycle Integration of Buildings, p.21.

- Adel, M., Cheng, Z. and Lei, Z., 2022. Integration of building information modeling (bim) and virtual design and construction (VDC) with stick-built construction to implement digital construction: A Canadian general contractor’s perspective. Buildings, 12(9), p.1337.

- Sepasgozar, S.M., Costin, A.M., Karimi, R., Shirowzhan, S., Abbasian, E. and Li, J., 2022. BIM and digital tools for state-of-the-art construction cost management. Buildings, 12(4), p.396.

- Baghalzadeh Shishehgarkhaneh, M., Keivani, A., Moehler, R.C., Jelodari, N. and Roshdi Laleh, S., 2022. Internet of Things (IoT), Building Information Modeling (BIM), and Digital Twin (DT) in construction industry: A review, bibliometric, and network analysis. Buildings, 12(10), p.1503.

- Honghong, S., Gang, Y., Haijiang, L., Tian, Z. and Annan, J., 2023. Digital twin enhanced BIM to shape full life cycle digital transformation for bridge engineering. Automation in Construction, 147, p.104736.

- Zhou, D., Pei, B., Li, X., Jiang, D. and Wen, L., 2024. Innovative BIM technology application in the construction management of highway. Scientific reports, 14(1), p.15298.

- Mayouf, M., Afsar, F., Iqbal, A., Javidroozi, V. and Mohandes, S.R., 2024. Synergies between digital construction technologies in smart buildings and smart city development to meet building users’ expectations. Heliyon, 10(8).

- He, R., Li, M., Gan, V.J. and Ma, J., 2021. BIM-enabled computerized design and digital fabrication of industrialized buildings: A case study. Journal of Cleaner Production, 278, p.123505.

- Jemal, K.M., Kabzhassarova, M., Shaimkhanov, R., Dikhanbayeva, D., Turkyilmaz, A., Durdyev, S. and Karaca, F., 2023. Facilitating circular economy strategies using digital construction tools: Framework development. Sustainability, 15(1), p.877.

- Gehring, M. and Rüppel, U., 2023. Data fusion approach for a digital construction logistics twin. Frontiers in Built Environment, 9, p.1145250.

- Tomczak, A., v Berlo, L., Krijnen, T., Borrmann, A. and Bolpagni, M., 2022, November. A review of methods to specify information requirements in digital construction projects. In IOP Conference Series: Earth and Environmental Science (Vol. 1101, No. 9, p. 092024). IOP Publishing.

- Pan, Y. and Zhang, L., 2023. Integrating BIM and AI for smart construction management: Current status and future directions. Archives of Computational Methods in Engineering, 30(2), pp.1081-1110.

- Deng, M., Menassa, C.C. and Kamat, V.R., 2021. From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. Journal of Information Technology in Construction, 26.

- Nour El-Din, M., Pereira, P.F., Poças Martins, J. and Ramos, N.M., 2022. Digital twins for construction assets using BIM standard specifications. Buildings, 12(12), p.2155.

- Alnaser, A.A., Hassan Ali, A., Elmousalami, H.H., Elyamany, A. and Gouda Mohamed, A., 2024. Assessment framework for BIM-digital twin readiness in the construction industry. Buildings, 14(1), p.268.

- Uzairuddin, S. and Jaiswal, M., 2022. Digital monitoring and modeling of construction supply chain management scheme with BIM and GIS: An overview. Materials Today: Proceedings, 65, pp.1908-1914.