- 1.0 Introduction Of MN5619 Research Project Assignment

- 1.1 Background

- 1.2 Research aim and objective

- 1.3 Research question

- 1.4 Motivation behind the research

- 2.0 Literature review

- 2.1 Empirical studies

- 2.2 Theories and models

- 2.3 Literature gap

- 3.0 Methodology

- 3.1 Research design

- 3.2 Research approach

- 3.3 Research Philosophy

- 4.0 Discussion

- 4.1 Introduction

- 4.2 Expected outcomes

- 4.2.1 The COVID-19 pandemic changed the supply chain

- 4.2.2 The new EV supply chain, automotive chip, shortage

- 4.2.3 Toyota’s marketing strategy

- 4.3 Discussion

- 5.0 Conclusion and recommendation

1.0 Introduction Of MN5619 Research Project Assignment

1.1 Background

In the automotive industry manufacturing and service operation management (MSOM) is the most important to the efficiency of the business, the quality services delivered and the profitability achieved. But today’s issues in this industry have affected even such giants as Toyota, for example. Toyota being famous for its lean manufacturing system and Just-in-Time (JIT) production, has faced several operational challenges in recent years requiring research into these areas. Continuing tasks involve a pressing consumption produced by the shortage of semiconductors available for purchase on a global scale, which affected Toyota severely getting in the way of its production line. This has created a shortage in the production of relevant key materials since the pandemic disrupted its production processes, and customer electronics increased demand outpaced its supply. Due to the implementation of JIT, the company has minimized its inventory expenses, but vulnerable to disruptions. Also, the shift to electric vehicles is both as threat and opportunity related to Toyota since there is a high growth of these cars. Currently, the legal requirements of Area for governments to transition to cleaner energy sources and to institute higher emission standards continue to drive the EV market demand.

24/7 support, expert writers, and fast delivery New Assignment Help is your best choice for trusted Assignment Help in the UK.

In this aspect, Toyota needs to incorporate those changes into the new automobile manufacturing processes to gain EV production efficiencies that do not compromise the ICE vehicle quality the company is associated with. This change entails major outlays on new technologies, tooling of factories, and training of employees.

1.2 Research aim and objective

Aim

The research objective of this study is to assess Toyota’s manufacturing and service operation management critically by highlighting the existing problem areas along with the prospects for improvement in relation to today’s manufacturing industry environment considering factors including the disruption of supply chains and integrating electric vehicles into manufacturing.

Objectives

- To evaluate the extent to which Toyota has been able to apply the lean manufacturing principles in reducing supply chain risks including the current shortage of semiconductors.

- To assess how Toyota Motors manufacturing processes and work efficiency will be affected by emerging market demand for electrical vehicles.

- To provide a clearer understanding related to Toyota’s service operation management, especially in the context of discovering how the organisation can enhance after-sales service through digital technology.

1.3 Research question

- How does the Toyota lean manufacturing system manage with disruptions within the supply chain for semiconductor deficiency?

- How the trend towards greater use of EVs influence Toyota’s established production line, and how should the company adapt its strategy in the changeover?

- What can Toyota’s service operations management do better for after-sales service provision and for customers’ satisfaction?

1.4 Motivation behind the research

The reasons for this research originate from emerging competition and issues characteristic for the nowadays developed automotive market, which influences Toyota. Toyota has always been considered to be a lean manufacturing firm and its operations have been efficient up to recent events like the shortage of semiconductors across the globe and the shift towards EVs. Also, the heightening delegation of customer service operations through electronic means introduces some new trends that put pressure on delivering quality after-sales service (Belhadi, et al. 2021). This research is to guide Toyota to understand how it can continue to maintain the launch and implementation of efficient world-class OM strategies that meet emerging changes within the market such as supply chain risks, change management for electric vehicles, and enhancing digital service delivery to customers.

2.0 Literature review

2.1 Empirical studies

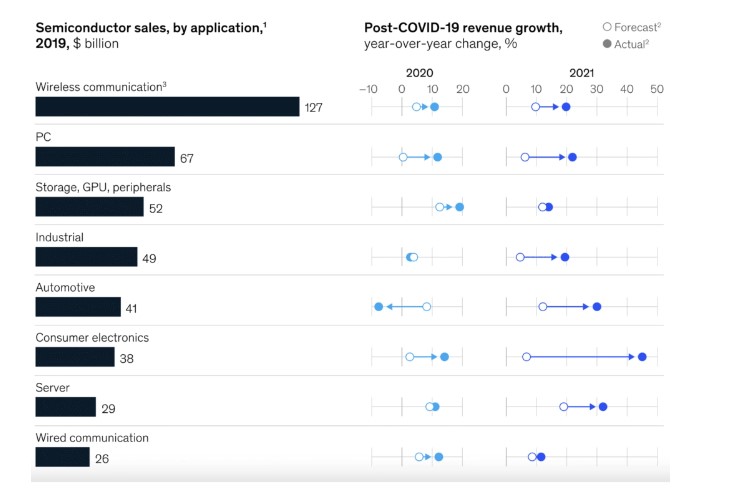

According to Batth, 2021, due to the pandemic situation over the world and increased demand and, thus, the lack of semiconductors in the global market, consumer needs have changed, and there is a demand across the range from the most simple microcontrollers to high-performance chips. While the complexity of the advanced semiconductor supply chain has been rising steadily, the access to these parts has been transferred into the hands of a few manufacturers, as it is the case of automotive industries (Batth, 2021). Toyota being proactive as usual for such potential disruptions changed its inventory management policies to keep replenishing chips from suppliers such as Denso. While Toyota stuck with its lean Just-In-Time (JIT) inventory control method on its side, this organization modified this by asking suppliers to hold more inventory to reduce delay. However, this was put to test in 2016 when natural disasters hit Toyota, and more profoundly, Covid-19 pandemic early this year. These occurrences forced the company to change its position, admit the need for Business Continuity Plan. In the current world, Toyota has built a disaster-ready supply chain and proactively controls key inventory assets throughout the supplier community. Clearly, it shows that Toyota until this level had always been ready to adjust to new changes that come withthe dynamic world of business.

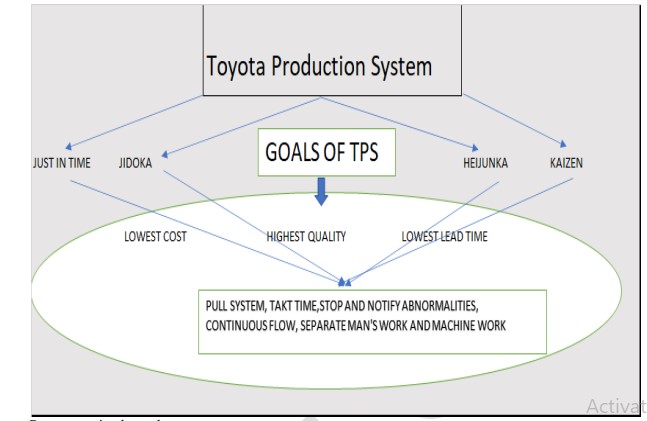

Figure 1: Toyota’s production system

According to Karrila, 2022, this thesis is concerned with issues in the management of the supply chain in the semiconductor industry from an industrial engineering orientation with the view to establishing an understanding of the current state of affairs, root causes, and possible ways forward. The relevant study is supplemented with a literature review that is focused on issues related to semiconductor manufacturing, market cycles, demand-supply shock, and bullwhip effect. Expert interviews add further evaluation to the study and reveal factors accelerating the shortage, major among them being the lock down, restricted trading, and consumers’ changing habits (Karrila, 2022). Premium semiconductors are coming back to normal, and while automotive is an industry with shortages it isn’t an incredibly lucrative business for chip makers because they seek older chips which are not profitable to make. Challenges to addressing the shortfall include lead times, regional focus in making chips, logistic factors such as ports, and containers. Also stacking for today’s structural problems involves factors such as high industry entrance barriers, competitive secrecy, and scarcity of talent especially in the semiconductor manufacturing process. It has also made the industry in terms of talent gap richer than the software sector but has also created a talent gap, especially in regions besides Asia. Meeting these systemic challenges needs better communication, collaboration, and resources devoted to the sector but risks will always persist because production is centralized globally.

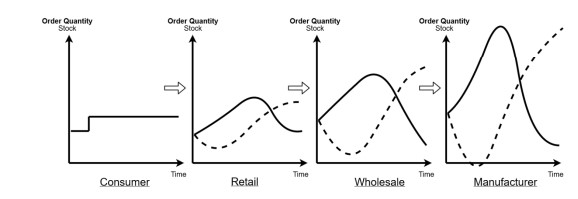

Figure 2: A relatively minor increase in demand causes

According to Kawai, 2022, this paper highlighted dynamic managerial capabilities and platform strategy frameworks which have been used to assess Toyota’s EV strategy. As for Toyota’s speed of entering the market of EVs, Toyota is considered as a late entrance in to the market compared with other competitors primarily at this point of time according to the current sales and production values despite the company’s experience and financial power in HV industry. Regarding to different questions pointed out that the delay is due to Toyota’s focus on HVs and employment instead of actively fighting global warming. Also, Toyota failed to measure the competitive rivalry from IT industries such as GAFA (Kawai, 2022). In the context of the objectives of the research paper, Toyota now looks unprepared for the war of EVs, it does not have adequate defense mechanisms or offense applications. Two key findings support this. President Toyoda’s lack of a strategic planning framework where this person aimed at a mere percentage reduction and Toyota’s good experiences with HV and air pollution regulations which have in fact slowed the company down. Furthermore, questions regarding the current organizational innovativeness of Toyota arises especially when they strived at HV and FCV technologies in the 1900s. The paper also finds that Toyota’s dynamic managerial capabilities are still lacking. But if Toyota makes correct adjustments in its strategy and based on it previous advantages, Toyota can still achieve satisfactory success in the market of BEVs.

Figure 3: Sequential framework of DMC

According to Rissanen, 2023, This research paper explores the current state of digitalization in the automotive industry and consequently analyses the role of digitalization in the aftersales business. With changing consumer preferences, OEMs are implementing better solutions to enhance customer benefits and workshop efficiency. The study is concerned with one of the most recent digital changes in the car workshops, namely, the increased use of video. Managers of the workshops involved in the study and OEM regional aftersales managers were interviewed in order to determine the opportunities and risks of digitalization (Rissanen, 2023). With a qualitative research method, the study aims at explaining why these benefits and challenges exist. It points out that IT applications which can be initiated by OEMs are critical to what has become a continuous transition to EVs and the overall transformation of the industry. These tools require proper communication between the OEMs, local managers, and employees to realize their implementation. The study also aims to understand the customers’ and staffs’ responses to this new digital services, especially the video.

According to Haryadi, et al. 2022, the factors that affect customer loyalty through after-sales service and customer satisfaction in Toyota. The findings of this study indicate that after sales service has a positive influence in enhancing consumer loyalty as well as customer satisfaction. There is an article note, that better after sale service increases customer satisfaction of consumers which increases consumer loyalty (Haryadi, et al. 2022). A major factor in the competitiveness of the manufacture of the product is the after-sales service where issues like repair, maintenance, and dealing with customer complaints are provided. Organizations that organize post-purchase service delivery are promoting satisfaction and customer loyalty since people are likely to remain loyal with a company that has been meeting their needs. The study also establishes that customer satisfaction affects consumer loyalty in a positive way as customer keep their loyalty with a given brand. The results obtained are in agreement with the formulated hypotheses that after-sales service has a considerable influence on consumer loyalty and customer satisfaction and that customer satisfaction stimulates customer loyalty. Thus, increasing the consumer’s loyalty is possible by strengthening the after-sales services or by a subsequent increase in customer satisfaction. These insights stress how after-sales service is critical to the development of future customer loyalty.

According to Boateng, and Comfort Agyekum Boateng, 2024, the application of Lean Thinking in the organizational strategic choices is effective in two ways. Through improving organizational productivity and through serving for consumers. Researchers mentioned and explained the integration of Lean Thinking and green practices, thus, improving operations productivity, and effective environmental management. Some researchers show that through an analysis of digital Lean Thinking, which satisfies the supply chains and a match with the strategic objectives (Boateng, and Comfort Agyekum Boateng, 2024). On the same note, Lean Thinking enables sustainability and digital transformation as part of a wider strategy. It is also related better to psychological strength. Researchers also illustrated how Lean Thinking enhances Industry 4.0 changes as well as organisational readiness, explaining how Lean Thinking creates the culture of the continuous learning process. This flexibility is very important in order to address the challenges of today. Further, researchers stressed the social aspect of Lean Thinking, revealing the changes it can help bring at the people level and enterprise sustainability. Lean Think promotes reduction in waste, improvement in overall performance, and organizaiton’s strategic planning for market relevant. Rapid globalization and integration of new technologies amplifier its importance, as pointed out the use of technology in the modern lean system. According to some researchers, flexibility became prescriptive as a result of globalization affecting Lean Thinking for sustainable longevity. Based on the Lean Thinking, efficiency, robustness, and culture flexibility are the main values of today’s competitive environment.

2.2 Theories and models

In MSOM of the automobile production, many theories and models have been established to enhance the production rate, cut costs, and satisfy consumers. To understand Toyota, these theories are part of their business and functional strategies, which could be examined by the following theories.

Lean Manufacturing and Just-in-time (JIT)

Toyota production system also known as lean manufacturing is one of the most revolutionary operational theories used in automotive production. The organization concentrates on dealing with waste and continuous improvement in order to increase efficiency and decrease costs while moving to higher product quality. It is a principle of Lean manufacturing in which Toyota have tried to make production of a commodity as near to the level of its consumption as possible so that there is no requirement of large stocks of inventories (Eldem, et al. 2022). But those sources have been disrupted as of late, such as the current issue with semiconductors. Lean manufacturing is often combined with TOC to help find restrictions within production to develop ways to maintain the right flow.

Six Sigma

Therefore, while waste is a critical issue at Toyota, Six Sigma is concerned with variation and defect rates in the production chain. Six Sigma is especially valuable in Toyota’s quality management systems that guarantee that a car produced meets the set quality requirements by the consumers (Holgado and Niess, 2023). However, the Six Sigma could be used in the Toyota’s transition from the producing traditional cars to electric vehicle (EV) production in order to look for more methods of avoiding defects as the company adapts to the new technologies and methods of manufacturing.

Total Quality Management

Another theory used in Toyota management is known as Total Quality Management (TQM). TQM is a management strategy that aims at the use of all the organisational members within the organisation to improve the quality of the organisation’s products and services on a permanent basis. This is an approach to organizational functioning consistent with Toyota’s long-established Kaizen policy, which makes use of feedback from all levels of an organization (Patel, 2023). In this respect, based on the meaning of quantitative and qualitative recognition of customer demands, understanding of the long-term success objective for Toyota, over the following points, it can be said that compared with the theory of business process reengineering (BPR), the scope of outlook for the strategic objectives of the total quality management or the global competitive strategy (TQM/GCS), is significantly broader.

Figure 4: TQM introduced by Toyota Motors

Supply Chain Resilience Framework

This seen with recent disruptions across the world, supply chain reliability has come as a major issue to Toyota, applied in Toyota’s operations. TQM focuses on the involvement of all organizational members, from top management to factory workers, in continuous quality improvement. This approach aligns with Toyota’s commitment to Kaizen, where feedback from every level of the organization is used to improve operations (Holgado and Niess, 2023). TQM’s emphasis on customer satisfaction and long-term success provides a broader framework for Toyota’s strategic goals, particularly as it adapts to changing consumer preferences for electric and hybrid vehicles.

Electronic commerce and Services Operation Management

Turning to Servitization Model of Service Operation Management, Toyota can implement it as sample of products and services to deliver more value to the target market members, from top management to factory workers, in continuous quality improvement. This approach aligns with Toyota’s commitment to Kaizen, where feedback from every level of the organization is used to improve operations (Gölgeci, et al. 2023). TQM’s emphasis on customer satisfaction and long-term success provides a broader framework for Toyota’s strategic goals, particularly as it adapts to changing consumer preferences for electric and hybrid vehicles.

Digitalization and Service Operations Management

In terms of service operations management, Toyota can leverage the Servitization Model, which focuses on integrating products with services to create additional value for customers. The new technologies, including artificial intelligence (AI), data analytics, and the internet of things (IoT) under Industry 4.0 are central to enhancing automation of after sale services and customer satisfaction (Kocabasoglu‐Hillmer, et al. 2023). These technologies can be used by Toyota to improve service delivery, and thereby guarantee that its customer service provision is on equal with current and future customer expectations of digitised services.

2.3 Literature gap

The literature discusses in detail Toyota’s performance and effectiveness based on lean manufacturing, JIT practices, and several supply chain management initiatives, however, some significant research limitations exist, specifically regarding current industry pressures. While many sources are collective, there is comparatively little completed in how Toyota can further advance its JIT system to overcome common supply chain interruptions such as the current chip scarcity. In the same way that there has been much debate about the move to electric vehicles (EVs), there is a limited publication which highlights the challenges that Toyota’s current manufacturing models must try to address rising EV demand without impacting productivity (MacDuffie, et al. 2021). Regarding the service operation management, literature covers different conventional approaches as are the models of the after-sales services, while the role of digitalisation in providing is not so explored according to the current literature. There is also lack of literature specifically in understanding how Toyota can utilize Industry 4.0 technologies for improving customer touchpoints and business adaptability. This research seeks to address these gaps through an analysis of Toyota’s management of these new challenges in manufacturing and service domains.

3.0 Methodology

3.1 Research design

The research employs a qualitative case study research approach concerned with Toyota’s manufacturing and service operations management. The main source will be secondary data, evidenced from company documents, sector, and industry magazines and newspapers, academic journals, and government information. This data will be analyzed to establish Toyota’s preparedness related to the scenarios of supply chain disruptions, shift to electric vehicles, and digitalization of service operations (Browning, et al. 2023). Published data from existing undertakings, studies, and records will be used to analyse Toyota’s operations, determine present problems, and propose recommendations based on principles such as lean production model and supply chain unpredictability theories.

3.2 Research approach

The research will adopt a qualitative research approach thus acknowledging the value of exploring issues in management of manufacturing and service operations at Toyota in greater depth. This approach facilitates comprehension of the perception around the present issues like supply chain disruption or change towards EVs (Karanam, et al. 2024). To collect the data through the use of academic journals, industry reports, and case studies to enable collection of contextual data are very significant aspects. This approach correlates with the research objectives of assessing and optimising its business effectiveness within a competitive environment.

3.3 Research Philosophy

Following this, the research shall adopt a constructivist research approach, which focuses on the interpretation of reality through the construction of meanings by individuals in Toyota’s manufacturing and service delivery. Constructivism recognises that knowledge is socially constructed and created therefore appropriate for understanding the operational issues of the automotive industry. Using such secondary data as industry reports and case studies, this works to consider its philosophy and make the analysis of various viewpoints on Toyota’s strategies, and other assessments to the changing market possible. It will also help to achieve a better understanding of how Toyota establishes and operates within its operating environment, and how it addresses current challenges.

4.0 Discussion

4.1 Introduction

This particular segment highlights that Toyota examines the fundamental findings from the manufacturing and service perspective of the company with emphasis on its approach to the existing industrial challenges. It emerges that, although Toyota has had phenomenal success with lean manufacturing and Just-In-Time processes, the current disruptions in the world’s supply chain, including a shortage in semiconductor chips, introduce a threat to Toyota. Also, coming to the era of electric vehicles, many changes are to be expected in Toyota’s production lines. Regarding services, the outcomes state the growing role of digitization in improving the service operations for customers.

4.2 Expected outcomes

4.2.1 The COVID-19 pandemic changed the supply chain

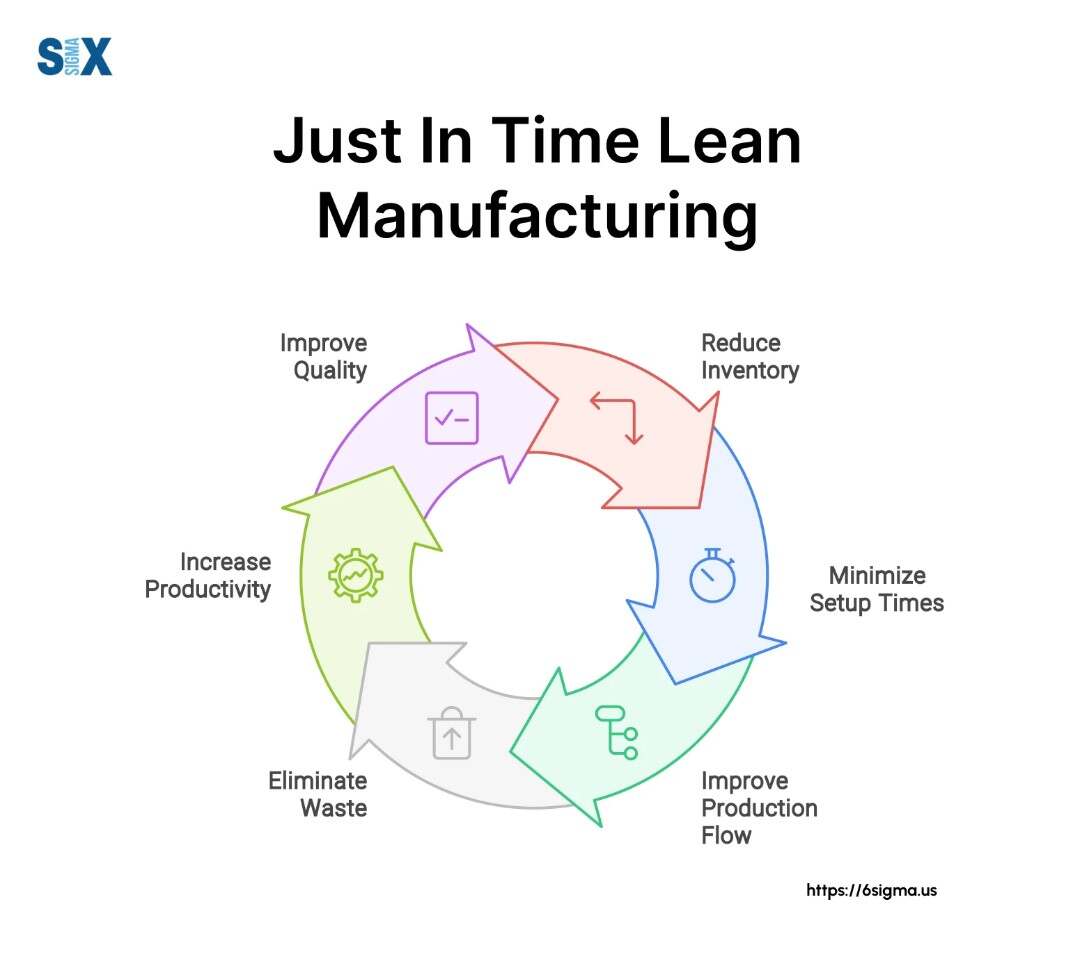

It is a well-known concept that through a reduction of inventory and associated costs, JIT acts as a means to cut social failure costs thus improving the totality of the networked system’s operations. Different key concepts of the system are pull production, meaning that production takes place only when there’s a call for the product and continuous flow, which rules out intervention between successive processes (Yu, et al. 2024). JIT depends on suppliers for stock supplies, and it involves low inventory accumulation, known as the lean inventory system. Purchasing management is done by using methods like Material Requirement Planning so as to check accuracy in inventory management while quality management is important to avoid disruptions due to poor quality goods. TQM stands for Total Quality Management, Kaizen for Continual Process Improvement, and Jidoka for Automation with involvement of human intelligence in decision making.

Figure 5: JIT production system in lean manufacturing

In the current complex manufacturing environment, JIT matches well with some Digital technologies such as Real-Time data analysis, which improves the inventory and production control, while JIT manufacturing does need highly coordinated processes, experienced workforce, and strong logistical networks, those managers who successfully implement JIT can effectively manage varying customer needs and therefore prepare for a stable long-term business.

4.2.2 The new EV supply chain, automotive chip, shortage

The market of electric vehicles is growing rapidly, large amounts are being directed to the development of battery production, creating increased demand for resources. In a bid to protect their supply chains, most manufacturers are gradually moving operations to the US where they stand to gain from adequate investment on EV infrastructure (Okorie, et al. 2020). Subscribers to EVs include Toyota, Honda, and Ford, all of which have pledged to increase production of electric cars; battery makers such as Piedmont Lithium and Cirba Solutions are likewise scaling up.

Figure 6: EV supply chain and chip shortage

One of the major changes in the supply pattern is a shift towards vertically integrated battery suppliers. These suppliers are assuming a new role, essentially becoming second tier, which is to manage Tier 1s for the propulsion platform while carmakers concentrate on integration of car body. This split supply chain required far fewer suppliers and that as ICE parts are likely to become obsolete because of the EV the millennium supply will require (Frieske and Stieler, 2022). Also, battery makers are coming up with recycling plans so that they can reclaim and renovate post-consumer batteries. However, there are still issues, such as ongoing shortage of computer chips across the world, which are still present. Lead times of automotive chips have never been longer because production and demand have been interfered by the pandemic conditions. Capacity expansion is an ideal solution and the commerce and manufacturing experts takes opinion that it will take at least until 2024.

4.2.3 Toyota’s marketing strategy

Toyota has achieved the best place in car manufacturing industry by providing quality cars and extended guarantee at a cheap cost for all over the world. The various strategies of the company branding are done by putting into consideration the provision of value and major branding points. Among the driving forces in Toyota’s success is the fact that the brand identifies with quality and reliability (Jagani, et al. 2024). This has been done through the constant delivery of strong and long lived cars which has given Toyota the image of a company delivering products worth the investment. The main brand association identified in the Toyota case is emerging technology and environmental responsibility. By bringing the first mass-production hybrid vehicle, Prius to the market, Toyota has established the solar technology as a way forward in creating sustainable automobile solutions standards. The Lean image has proved effective in increasing consumer consumer consciousness about green products which has enabled Toyota to separate itself from competitors. Creativity is one of the core values of the Toyota Company. The company conducts strong emphasis on research and developmental departments and produces new technologies constantly, safety features as well like Toyota Safety Sense (Mzavanadze and Tolocka, 2024). It also invests in creating vehicles, which will appeal to the changing market needs, including hybrids and electric cars to remain relevant in the competitive market and keep up with advances in the environmental sustainability agenda.

Figure 7: Toyota’s marketing strategies

Besides advertising, Toyota communicates with its potential buyers sponsoring large international contests, including the Olympic Games and NASCAR, it thus associates its brand with the concepts of high-quality performance. This strategic sponsorship placed Toyota at advantage position by increasing its visibility to the world and the corresponding brand image. Here, branding does not enclose Toyota on the aspect of product differentiation but also on corporate social responsibility (Azadegan and Dooley, 2021). There is information related to sustainability goals and the company works on achieving environmental initiatives such as decrease of emissions and achieving carbon neutrality. All these efforts are appealing to an environmentally conscious customer base and at the same time enhance the image of the Toyota Company as a progressive and environmentally friendly company.

4.3 Discussion

In the automotive sector, Toyota has taken a strategic positioning in marketing its automobiles as those with certainty, reliability, innovativeness, and quality. One of the major strategies of the company’s branding includes focus on delivering value while at the same time building brand familiarity in various ways. The organization’s core competency which is a strong benchmark with regards to quality and reliability is one of Toyota’s most important strategic assets. Consequently, through rolling out products that are long lasting and strong, Toyota has cultivated a customer confidence that is well placed on the cars. This company is designed based on Toyota’s powerful brand image that focuses on technological aspects and environmental concerns (Cooper, 2024). The release of Prius, the world’s first production hybrid vehicle enabled Toyota to establish dominance in the advertising of hybrid technology elements as a green approach to automobile building. This green image has been well received due to increasing awareness of the environment throughout the globe and has allowed Toyota to set itself apart as a competitor. Creativity is a core strategic value of the Toyota brand. It spends a great deal conducting research as evidenced through its continuous innovation of new products, a driving factor found in its safety features TSS. Another aspect is that Toyota also aims at making cars that best suit the needs of its clients in the future when most vehicles will switch to hybrids and electric vehicles.

Toyota’s brand communication strategy is affected by the need to distribute three fundamental messages to target audiences. The company’s main advertising strategies include television and online advertising; claim that Nissan is committed to offering utility with quality, efficiency, and advanced technology vehicles. Moreover, Toyota leverages on ways such as sponsorships of global sporting events like the Olympic Games, NASCAR, and others where customer images are built by associating themselves with drinks, excellence, and high performance. In this way, this strategic sponsorship improves the Company’s exposure for Toyota and strengthens the brand on the international level (Ochonogor, et al. 2023). This study proved that Toyota is using pull production, continuous flow, takt time, and kanban. The Toyota has the capability to produce vehicles only when necessary thereby showing flexibility in their operations due to pull production. This way allows for setting loose tolerance limits and shorter production runs, which in turn facilitates timely changes that target fulfilling consumers needs. However, the JIT system’s dependence on suppliers and minimisation of stocks have their weaknesses, especially in problematic areas such as the present global chip scarcity. These disruptions signify the enhancement of Supply chain dependence for Toyota without sacrificing the lean principle which is in line with the research objective of increasing effectiveness in operations.

Another important and challenging process that occupies an essential place in Toyota’s development plan is the transition to electric vehicles (EVs). The change towards EV manufacturing brings up new issues in the supply network, particularly battery acquisition and the ever-present chip crisis (Smorodinskaya, et al. 2021). With increasing demand for EVs, the ICE car components become redundant, and Toyota has to change its supply chain and production line. One notable trend in this area is the coming of age of the so-called vertically integrated battery suppliers that are taking over more of the propulsion platform while allowing automakers such as Toyota to integrate it into the vehicle. Also, battery producers are diversifying into recycling with a view of recycling post-consumer batteries which has develop into a trend within the business. Reflecting on the JIT production system of Toyota, its response to the supply chain of electric vehicles, and its marketing policies the author has identified that while effectively managing its production and supply chain the company cannot afford to ignore emerging problems (Mensah, 2024). Ensuring the uninterrupted supply of parts and materials, increasing the adaptability of production for electric vehicles, and preserving the company’s brand image, which all correspond with the research goals of increasing operational reliability, productivity, and customer satisfaction.

5.0 Conclusion and recommendation

5.1 Conclusion

Therefore, this study has analyzed Toyota’s manufacturing and service activities, covering Just-in-Time production, the shift to EVs, and supply issues, including semiconductor scarcity. Toyota has applied lean manufacturing principles in order to optimise its supply chain, yet these principles have been challenged by recent disruptions indicating the quality of supply chain flexibility. Moreover, change over to electric vehicles means significant changes to manufacturing processes and suppliers that are involved in it. The assimilation of new technologies and adherence to environmental progammes has served to enhance Toyota’s strategic position in the market place. However, in order to remain a competitive player in the context of a constantly transforming and more challenging global automotive environment, Toyota has to keep reinventing many of its operational activities; these have to be as flexible, effective, and environmentally friendly as possible on a global scale.

5.2 Recommendation

- Diversify Supply Chain: Toyota must diversify its suppliers’ base and avoid heavy reliance in particular suppliers for important commodities like semiconductors. Evaluating for several suppliers in diverse areas minimizes the impact of disruptions from around the world (Pu, et al. 2021).

- Strengthen Digital Integration: The introduced advanced real-time data analytics and Industry 4.0 technologies can improve the practicality of inventory and production monitoring in the Just-in-Time system in cases of unexpected changes.

- Increase Focus on Electric Vehicle (EV) Production: Toyota should act on the context by upgrading its assembly line of electric vehicles, which should comprise establishing long-term relationships with battery manufacturers. This includes linking vertically to the potential of keeping raw material supply chain under control by developing recycling programs (Sodhi, et al. 2023).

- Adopt a Flexible Manufacturing Approach: As the shift from internal combustion engines to EVs is becoming more apparent, Toyota should develop more flexibility in its lines so as to meet the changing needs without straying off from efficiency.

Reference list

Journals

- Azadegan, A. and Dooley, K., 2021. A typology of supply network resilience strategies: complex collaborations in a complex world. Journal of Supply Chain Management, 57(1), pp.17-26.

- Batth, V., 2021. Toyota motor corporation: Just in time (jit) management strategy or beyond. Journal of Case Research, 12(1), pp.18-27.

- Belhadi, A., Kamble, S., Jabbour, C.J.C., Gunasekaran, A., Ndubisi, N.O. and Venkatesh, M., 2021. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technological forecasting and social change, 163, p.120447.

- Boateng, P.A. and Comfort Agyekum Boateng, M.B.A., 2024. Interdisciplinary Nexus of Lean Thinking and Strategy: An Exploration in to Psychological Resilience, Cultural Adaptability, and Economic Sustainability. International Journal of Research and Scientific Innovation, 10(12), pp.167-175.

- Browning, T., Kumar, M., Sanders, N., Sodhi, M.S., Thürer, M. and Tortorella, G.L., 2023. From supply chain risk to system-wide disruptions: research opportunities in forecasting, risk management and product design. International Journal of Operations & Production Management, 43(12), pp.1841-1858.

- Cooper, M., 2024. Agile Procurement in a Changing Marketplace: Examining Adaptability and Responsiveness in Supply Chain Management.

- Eldem, B., Kluczek, A. and Bagiński, J., 2022. The COVID-19 impact on supply chain operations of automotive industry: A case study of sustainability 4.0 based on Sense–Adapt–Transform framework. Sustainability, 14(10), p.5855.

- Frieske, B. and Stieler, S., 2022. The “semiconductor crisis” as a result of the COVID-19 pandemic and impacts on the automotive industry and its supply chains. World Electric Vehicle Journal, 13(10), p.189.

- Gölgeci, I., Gligor, D.M., Bayraktar, E. and Delen, D., 2023. Reimagining global value chains in the face of extreme events and contexts: Recent insights and future research opportunities. Journal of Business Research, 160, p.113721.

- Haryadi, D., Haerofiatna, H. and Alfarizi, A.W., 2022. The Role of After Sales Service on Customer Loyalty Mediated by Customer Satisfaction. eCo-Buss, 5(2), pp.583-592.

- Holgado, M. and Niess, A., 2023. Resilience in global supply chains: Analysis of responses, recovery actions and strategic changes triggered by major disruptions. Supply Chain Management: An International Journal, 28(6), pp.1040-1059.

- Holgado, M. and Niess, A., 2023. Resilience in global supply chains: Analysis of responses, recovery actions and strategic changes triggered by major disruptions. Supply Chain Management: An International Journal, 28(6), pp.1040-1059.

- Jagani, S., Marsillac, E. and Hong, P., 2024. The Electric Vehicle Supply Chain Ecosystem: Changing Roles of Automotive Suppliers. Sustainability, 16(4), p.1570.

- Karanam, R.K., Sachani, D.K., Natakam, V.M., Yarlagadda, V.K. and Kothapalli, K.R.V., 2024. Resilient Supply Chains: Strategies for Managing Disruptions in a Globalized Economy. American Journal of Trade and Policy, 11(1), pp.7-16.

- Karrila, I., 2022. Supply chain challenges in the semiconductor industry (Master's thesis, I. Karrila).

- Kawai, T., 2022. Evaluation of Toyota’s Strategy for Electric Vehicles in Counteracting Platformers—Based on the Theories of Dynamic Managerial Capabilities and Dynamic Platform Strategy—. Journal of Strategic Management Studies, 14(1), pp.67-87.

- Kocabasoglu‐Hillmer, C., Roden, S., Vanpoucke, E., Son, B.G. and Lewis, M.W., 2023. Radical innovations as supply chain disruptions? A paradox between change and stability. Journal of Supply Chain Management, 59(3), pp.3-19.

- MacDuffie, P.J., Fujimoto, T. and Heller, D.A., 2021. Building Supply-Chain Continuity Capabilities in a Post-Pandemic World. Wharton School, University of Pennsylvania.

- Mensah, M., 2024. Effective Communication Strategy During Crisis: A Case of the 2010 Toyota Recall Crisis.

- Mzavanadze, N. and Tolocka, E., 2024. Enhancing Supply Chain Synchronisation in the Fast Moving Consumer Goods Industry. Vilnius University Proceedings, 49, pp.6-12.

- Ochonogor, K.N., Osho, G.S., Anoka, C.O. and Ojumu, O., 2023. The COVID-19 pandemic and supply chain disruption: an analysis of the semiconductor industry’s resilience. Int. J. Tech. Sci. Res. Eng., 6(1), pp.7-18.

- Okorie, O., Subramoniam, R., Charnley, F., Patsavellas, J., Widdifield, D. and Salonitis, K., 2020. Manufacturing in the time of COVID-19: an assessment of barriers and enablers. IEEE Engineering Management Review, 48(3), pp.167-175.

- Pandya, D. and Khanzode, A., BUILDING RESILIENT SUPPLY CHAINS: EXAMINING STRATEGIES FOR RESILIENT SUPPLY CHAINS. Operations Management on the New Frontier: Bridging Established Norms and Contemporary Innovations, p.17.

- Patel, K.R., 2023. Enhancing global supply chain resilience: Effective strategies for mitigating disruptions in an interconnected world. BULLET: Jurnal Multidisiplin Ilmu, 2(1), pp.257-264.

- Pu, X., Chen, M., Cai, Z., Chong, A.Y.L. and Tan, K.H., 2021. Managing emergency situations with lean and advanced manufacturing technologies: an empirical study on the Rumbia typhoon disaster. International Journal of Operations & Production Management, 41(9), pp.1442-1468.

- Rissanen, M., 2023. Digitalization of automotive industry: Use of video services in the after sales market.

- Smorodinskaya, N.V., Katukov, D.D. and Malygin, V.E., 2021. Global value chains in the age of uncertainty: advantages, vulnerabilities, and ways for enhancing resilience. Baltic Region, 13(3), pp.78-107.

- Yu, W., Wong, C.Y., Jacobs, M.A. and Chavez, R., 2024. What are the right configurations of just-in-time and just-in-case when supply chain shocks increase?. International Journal of Production Economics, 276, p.109352.